In the realm of shrimp feed production, the quality of feed pellets plays a crucial role in determining the health, growth, and overall productivity of shrimp farms. One of the key components that significantly enhances the performance of shrimp feed pellet machines is the multi-layer conditioner. This article explores the reasons why equipping shrimp feed pellet machines with multi-layer conditioners is essential for producing high-quality shrimp feed.

Understanding the Multi-Layer Conditioner

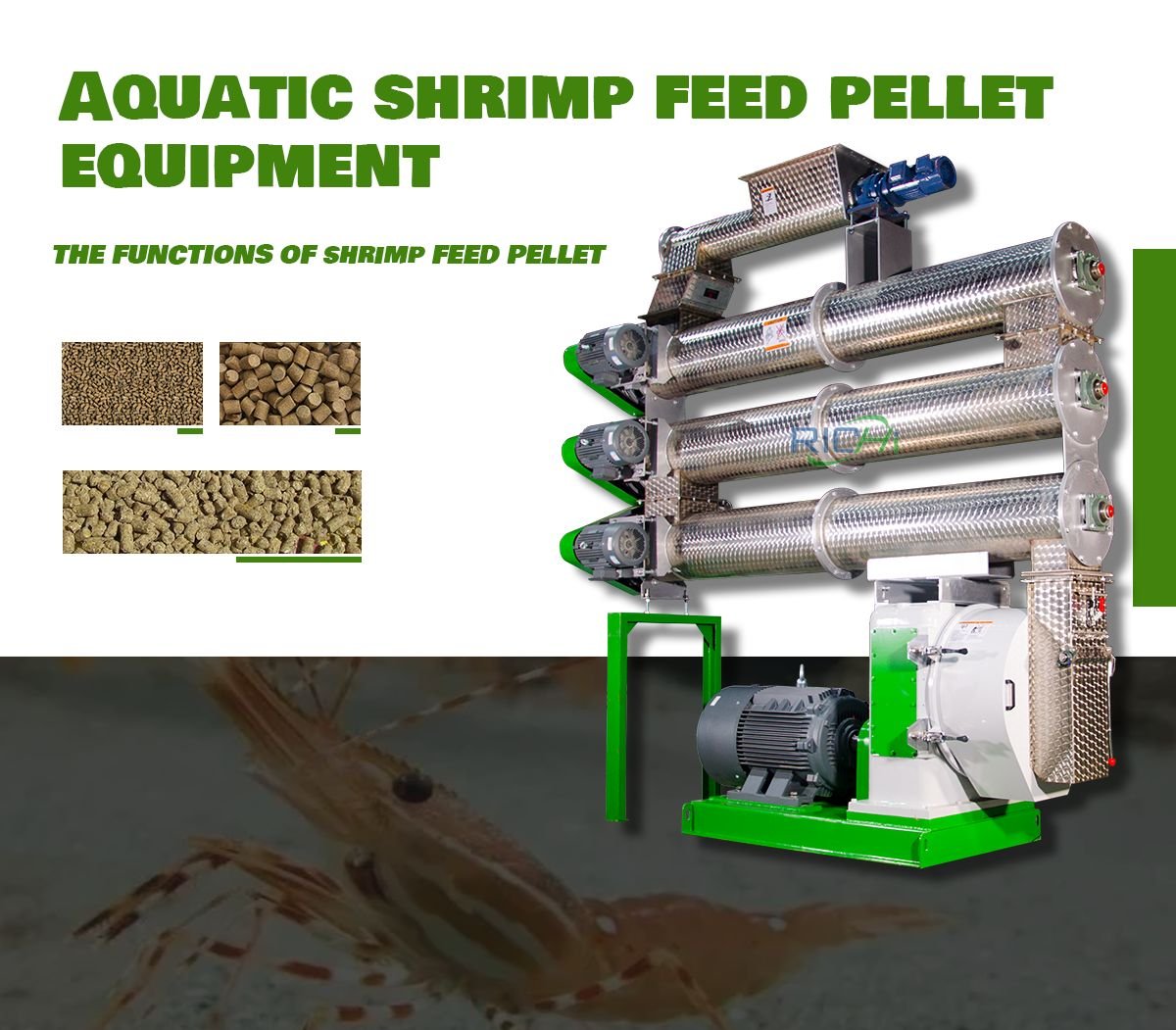

Before delving into its importance, it’s crucial to understand what a multi-layer conditioner is. A multi-layer conditioner is an advanced pre-processing unit that prepares the feed mixture before it enters the pellet die. It typically consists of two to four chambers or layers, each designed to perform specific functions in the conditioning process.Key Reasons for Equipping Multi-Layer Conditioners

- Enhanced Moisture Distribution

One of the primary reasons for using a multi-layer conditioner is to achieve superior moisture distribution throughout the feed mixture. Shrimp feed often requires higher moisture content (up to 17-18%) compared to other animal feeds. The multiple layers allow for gradual and uniform moisture addition, ensuring that each particle of the feed mixture is adequately hydrated. This uniform moisture distribution is crucial for:

- Improved pellet binding

- Enhanced gelatinization of starches

- Better overall pellet quality and water stability

- Optimized Starch Gelatinization

Starch gelatinization is a critical process in shrimp feed production, as it improves the digestibility of the feed. The multi-layer conditioner provides:

- Longer retention time for the feed mixture

- Controlled temperature increase across layers

- Gradual moisture addition

These factors combine to create ideal conditions for optimal starch gelatinization, resulting in more digestible and nutritionally efficient feed pellets.

- Improved Protein Denaturation

Shrimp feed typically contains high levels of protein. The multi-layer conditioner helps in the partial denaturation of proteins, which is beneficial because:

- It improves protein digestibility

- It enhances the binding properties of the feed mixture

- It contributes to better pellet durability and water stability

- Better Control Over Processing Parameters

Multi-layer conditioners offer greater flexibility and control over various processing parameters:

- Temperature: Each layer can be set to a different temperature, allowing for a gradual increase in heat exposure.

- Moisture: Steam and water can be added at different stages for precise moisture control.

- Retention Time: The multiple layers increase the overall retention time, allowing for more thorough conditioning.

This level of control enables feed manufacturers to optimize the conditioning process for different feed formulations and shrimp species requirements. (ring die pellet machine)

- Enhanced Feed Safety

The extended conditioning process in a multi-layer system contributes to feed safety by:

- Reducing harmful microorganisms through prolonged heat exposure

- Improving the effectiveness of any heat-activated feed additives

- Ensuring more uniform treatment of the entire feed batch

- Improved Pellet Durability and Water Stability

Shrimp are slow feeders, and their feed needs to remain stable in water for extended periods. The multi-layer conditioning process contributes to improved pellet durability and water stability by:

- Enhancing the binding between feed particles

- Promoting better gelatinization and protein denaturation

- Allowing for more thorough hydration of binders and other ingredients

- Energy Efficiency

While it might seem that multiple conditioning layers would increase energy consumption, in many cases, the opposite is true. The multi-layer design allows for:

- More efficient use of steam and heat

- Reduced energy requirements in the pelleting process due to better-prepared feed mixture

- Potential for heat recovery between layers

- Flexibility in Ingredient Processing

Shrimp feed formulations can vary significantly based on available ingredients and specific nutritional requirements. Multi-layer conditioners provide the flexibility to process a wide range of ingredients effectively, including:

- Plant-based proteins

- Animal by-products

- Various types of starches and binders

- Heat-sensitive additives (added in later stages of conditioning)

- Improved Production Efficiency

By thoroughly preparing the feed mixture before pelleting, multi-layer conditioners contribute to overall production efficiency:

- Reduced wear on pellet dies and rollers

- Higher throughput rates

- Fewer production interruptions due to poor pellet quality

- Better Nutrient Retention

The controlled and gradual conditioning process in a multi-layer system helps in better retention of heat-sensitive nutrients. This is particularly important for:

- Vitamins and certain amino acids

- Specialized feed additives

- Pigments used for shrimp coloration

- Customization for Different Feed Types

Multi-layer conditioners allow for customization of the conditioning process for different types of shrimp feed:

- Starter feeds

- Grower feeds

- Finisher feeds

- Broodstock feeds

Each type can be optimized by adjusting the parameters in different layers of the conditioner.

- Improved Feed Conversion Ratio (FCR)

The cumulative effect of all the above benefits leads to an improved Feed Conversion Ratio. Better-conditioned feed results in:

- Higher digestibility

- Reduced feed waste

- More efficient nutrient utilization by shrimp

Challenges and ConsiderationsWhile multi-layer conditioners offer numerous benefits, there are some challenges to consider:

- Higher initial investment cost

- Increased complexity in operation and maintenance

- Need for skilled operators to optimize the conditioning process

- Potential for over-processing if not properly controlled

Conclusion

The incorporation of multi-layer conditioners in shrimp feed pellet machines represents a significant advancement in feed production technology. These sophisticated systems address many of the unique challenges associated with shrimp feed production, including the need for high moisture content, excellent water stability, and optimal nutrient digestibility.

By providing enhanced control over the conditioning process, multi-layer conditioners enable feed manufacturers to produce high-quality shrimp feed pellets that meet the specific nutritional requirements of different shrimp species and growth stages. The benefits extend beyond just pellet quality, impacting overall farm productivity, feed efficiency, and environmental sustainability.

As the shrimp aquaculture industry continues to grow and face new challenges, the role of advanced feed production technologies becomes increasingly critical. The multi-layer conditioner is not just an add-on to the shrimp feed pellet machine; it’s an essential component that significantly contributes to the production of superior shrimp feed, ultimately supporting the success and sustainability of shrimp farming operations worldwide.