Introduction

The global aquaculture industry is growing rapidly, and the demand for high-quality fish feed is increasing accordingly. Fish feed production plants play a critical role in this industry by providing the necessary feed to support the health and growth of fish. Building a fish feed production plant involves several key steps, from understanding the types of fish feed available to selecting the right equipment and production processes. This comprehensive guide will walk you through each step, ensuring you have the knowledge needed to establish a successful fish feed production facility.

Types of Fish Feed Available

Understanding the types of fish feed available is the first step in building a fish feed production plant. Fish feed can be classified into various categories based on its form and nutritional content. The two primary forms of fish feed are:

- Floating Fish Feed: This type of feed is designed to float on the water’s surface, making it easier for fish to locate and consume. Floating fish feed is ideal for species that feed near the surface, such as tilapia and catfish. It also allows farmers to monitor feed consumption and reduce waste.

- Sinking Fish Feed: Sinking feed is formulated to sink to the bottom of the water, making it suitable for bottom-feeding species like shrimp and some types of catfish. It is also preferred in situations where floating feed might drift away due to water currents.

In addition to these forms, fish feed can be further categorized based on its nutritional composition, including protein, fat, fiber, vitamins, and minerals. The choice of feed type depends on the species being farmed, their growth stage, and the specific farming environment.

How Is Fish Feed Made?

The production of fish feed involves several stages, each crucial to ensuring the final product meets the nutritional and physical requirements of the target species. The general process includes the following steps:

- Ingredient Selection and Preparation: The first step involves selecting raw materials, such as fish meal, soybean meal, grains, and vitamins. These ingredients are carefully chosen to provide the necessary nutrients for fish growth. The selected materials are then cleaned, ground, and mixed to achieve a uniform blend.

- Mixing: The prepared ingredients are mixed to create a homogenous feed mixture. This step ensures that all the nutrients are evenly distributed throughout the feed.

- Conditioning: The mixed feed is then conditioned by adding steam, moisture, and heat. This process improves the binding properties of the feed and prepares it for extrusion or pelleting.

- Extrusion or Pelleting: The conditioned feed is passed through an extruder or pelleting machine to form it into the desired shape and size. Extrusion produces floating feed by expanding the feed particles, while pelleting typically results in sinking feed.

- Drying: The formed feed is dried to remove excess moisture, ensuring it has a longer shelf life and remains stable during storage.

- Cooling: After drying, the feed is cooled to room temperature to prevent mold growth and to maintain its quality.

- Coating: In some cases, oils, fats, or other additives are applied to the feed surface to enhance its nutritional value or improve palatability.

- Packaging: The final product is packaged in bags or bulk containers, ready for distribution to fish farms.

Floating vs. Sinking Fish Feed: Key Differences

The choice between floating and sinking fish feed depends on several factors, including the species being farmed, feeding behavior, and water conditions. Here are the key differences between the two:

- Buoyancy: Floating feed remains on the water’s surface, while sinking feed settles at the bottom. This difference in buoyancy determines how the feed is consumed by the fish.

- Feeding Behavior: Surface-feeding species, such as tilapia, prefer floating feed, while bottom-feeding species, like shrimp, thrive on sinking feed.

- Monitoring and Waste Reduction: Floating feed allows farmers to monitor feeding behavior and reduce waste, as uneaten feed can be easily removed. Sinking feed, on the other hand, may lead to more waste if not properly managed.

- Water Stability: Floating feed is less likely to disintegrate in water, reducing the risk of water pollution. Sinking feed may break down over time, potentially affecting water quality.

Advantages of a Fish Pellet Extruder

A fish pellet extruder is an essential piece of equipment in the fish feed production process, particularly for producing floating feed. The advantages of using a fish pellet extruder include:

- Versatility: Extruders can produce a wide range of feed types, including floating and sinking feed, with different sizes and shapes.

- Nutrient Retention: The extrusion process enhances the digestibility of feed and retains essential nutrients, leading to better growth and health of fish.

- Improved Feed Quality: Extruded feed has a uniform shape and size, ensuring consistent consumption by fish. It also has a higher water stability, reducing the risk of pollution.

- Energy Efficiency: Modern extruders are designed to be energy-efficient, reducing operational costs.

Advantages of a Fish Feed Pelleting Machine

A fish feed pelleting machine is another crucial piece of equipment, especially for producing sinking feed. The advantages of using a fish feed pelleting machine include:

- Cost-Effectiveness: Pelleting machines are typically less expensive than extruders, making them a cost-effective option for producing sinking feed.

- Durability: Pelleted feed is durable and can withstand handling and transportation without breaking down.

- Customizable Feed: Pelleting machines allow for the production of feed with specific sizes and densities, tailored to the needs of different fish species.

- Lower Operational Costs: Pelleting requires less energy than extrusion, leading to lower operational costs.

Fish Feed Bulking Machine vs. Pelleting Machine: What’s the Difference?

A fish feed bulking machine and a pelleting machine serve different purposes in the feed production process. Understanding the difference between the two is important for selecting the right equipment for your production plant.

- Function: A bulking machine is primarily used to increase the volume and bulk of the feed by expanding it during processing. It is often used in conjunction with an extruder to produce floating feed. A pelleting machine, on the other hand, compacts the feed into dense pellets, typically used for sinking feed.

- Feed Type: Bulking machines are associated with the production of floating feed, while pelleting machines are used for sinking feed.

- Energy Consumption: Bulking machines generally consume more energy due to the expansion process, whereas pelleting machines are more energy-efficient.

- Final Product: The final product from a bulking machine is typically lighter and more porous, while pelleted feed is dense and firm.

How to Build a Fish Feed Production Plant

Building a fish feed production plant involves several critical steps. Here’s a step-by-step guide to help you through the process:

- Conduct Market Research: Begin by researching the market demand for fish feed in your target region. Identify the species that are most commonly farmed and the type of feed they require.

- Develop a Business Plan: Create a detailed business plan that outlines your production goals, target market, budget, and projected revenue. Include a feasibility study to assess the viability of the plant.

- Select a Suitable Location: Choose a location that is easily accessible, has adequate water and power supply, and is close to raw material sources and fish farms.

- Design the Plant Layout: Work with engineers and architects to design the layout of the plant. Ensure the design optimizes workflow, from raw material intake to final product packaging.

- Obtain Necessary Permits: Secure all necessary permits and licenses from local authorities to operate the production plant.

- Purchase Equipment: Select the appropriate equipment for your production needs, including mixers, extruders, pelleting machines, dryers, and packaging machines. Ensure the equipment meets industry standards and is energy-efficient.

- Install and Commission Equipment: Hire qualified technicians to install and commission the equipment. Test the equipment to ensure it operates efficiently and produces high-quality feed.

- Hire and Train Staff: Recruit skilled workers to operate the plant and provide them with the necessary training on equipment operation, safety protocols, and quality control.

- Establish Quality Control Measures: Implement strict quality control measures to ensure the feed meets nutritional and safety standards. Regularly test the feed for nutrient content, moisture levels, and other key parameters.

- Market and Distribute the Feed: Develop a marketing strategy to promote your fish feed to local fish farms. Establish distribution channels to ensure timely delivery of feed to your customers.

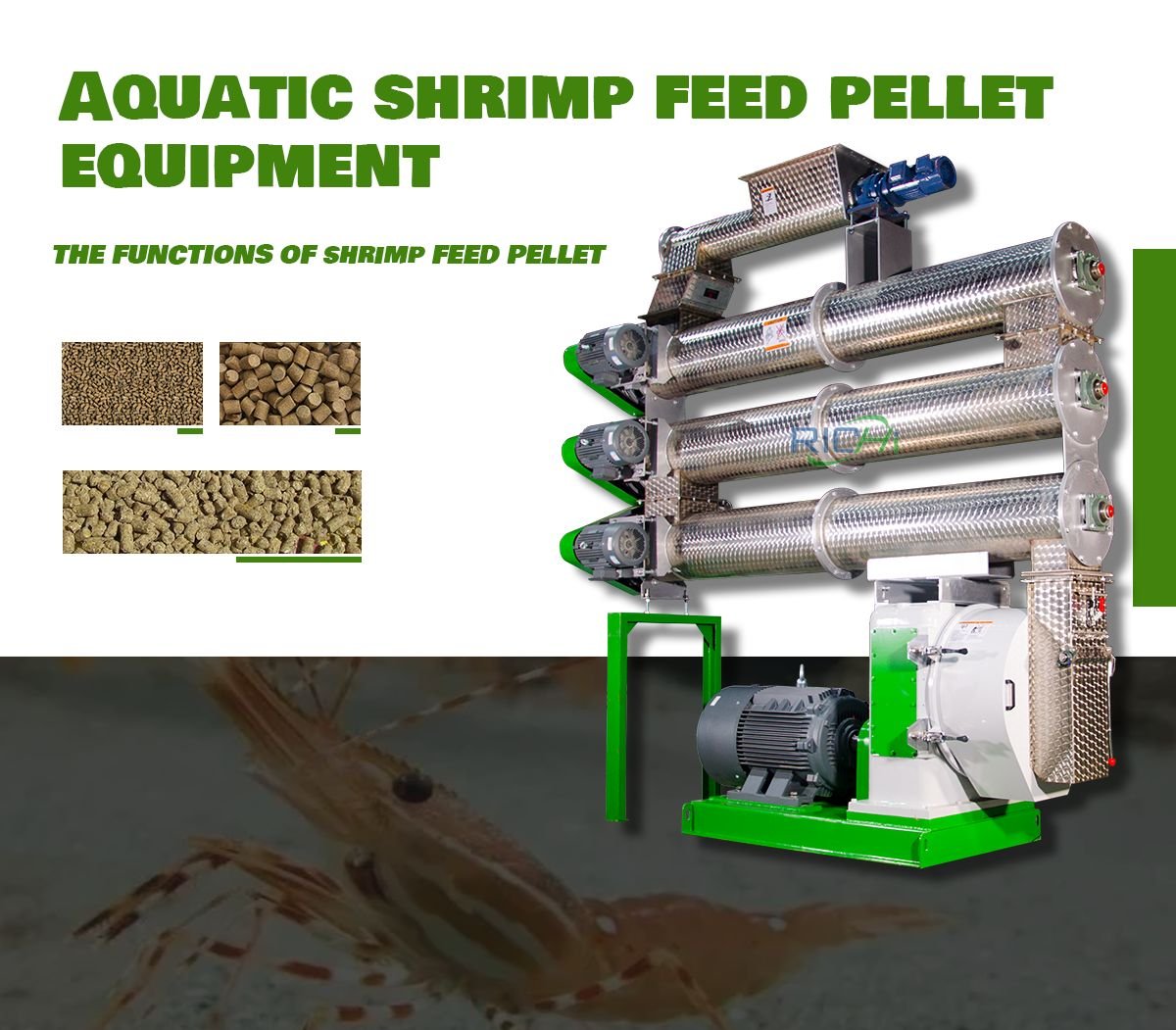

Can a Fish Feed Production Plant Produce Shrimp Feed?

Yes, a fish feed production plant can be adapted to produce shrimp feed. The process of making shrimp feed is similar to fish feed production, but with some adjustments to the formulation and processing techniques. Shrimp feed typically requires higher protein content and specific amino acid profiles. Additionally, shrimp feed is often produced as small, sinking pellets to suit the feeding habits of shrimp. By adjusting the feed formulation and using the appropriate equipment, such as pelleting machines, a fish feed production plant can efficiently produce high-quality shrimp feed.

Where to Buy Fish Feed Production Plant Equipment

Selecting the right equipment is crucial to the success of your fish feed production plant. When looking to purchase equipment, consider the following factors:

- Quality: Ensure the equipment is made from durable materials and meets industry standards. High-quality equipment will have a longer lifespan and require less maintenance.

- Supplier Reputation: Choose a supplier with a strong reputation in the industry. Research customer reviews and ask for references to verify the supplier’s credibility.

- After-Sales Support: Look for suppliers that offer comprehensive after-sales support, including installation, training, and maintenance services.

- Cost: Compare prices from different suppliers to ensure you are getting the best value for your investment.

Fish Feed Production Equipment from RICHI Machinery

RICHI Machinery is a leading manufacturer of fish feed production equipment, offering a wide range of solutions tailored to the needs of the aquaculture industry. RICHI’s equipment is known for its durability, efficiency, and versatility, making it an ideal choice for both small-scale and large-scale production plants. The company provides a comprehensive range of equipment, including mixers, extruders, pelleting machines, dryers, and packaging systems, all designed to meet the highest industry standards.

How to Find RICHI Machinery

Finding and purchasing fish feed production equipment from RICHI Machinery is straightforward. You can visit the RICHI Machinery website to explore their product catalog, request a quote, or contact their sales team for personalized assistance. Additionally, RICHI Machinery has a global network of distributors and agents, making it easy to find their products in your region. Whether you are setting up a new production plant or upgrading existing equipment, RICHI Machinery offers the expertise and support needed to help you succeed.

Conclusion

Building a fish feed production plant is a complex but rewarding endeavor that requires careful planning, the right equipment, and a deep understanding of the fish feed production process. By following the steps outlined in this guide, you can establish a successful production facility that meets the growing demand for high-quality fish feed. With the right approach and the support of reputable equipment suppliers like RICHI Machinery, your fish feed production plant can become a key player in the aquaculture industry.