Poultry Feed Machine

Our poultry feed machine is a complete system of equipment for poultry feed production. It can process raw materials such as corn, soybean meal, barley, and fish meal into feed pellets, powder, or crushed feed suitable for poultry such as chickens and ducks, helping farms and feed mills achieve stable and efficient self-production of feed.

Poultry feed pellet production equipment solution

chicken feed machine

duck feed machine

goose feed machine

laying hen feed machine

turkey feed machine

bird feed machine

quail feed machine

Pigeon feed machine

What type of poultry feed do you need?

Common poultry feeds include pelleted feed, mash feed, crumbled feed, and premixes. Different types of poultry and different growth stages require different feed forms.

Laying hens prefer mash feed, while broiler chickens benefit from pelleted feed, which is more nutritionally concentrated and has a higher feed conversion rate. Crumbled feed is suitable for chicks and poultry in transitional stages, while premixes provide nutritional supplements through precise ingredient ratios.

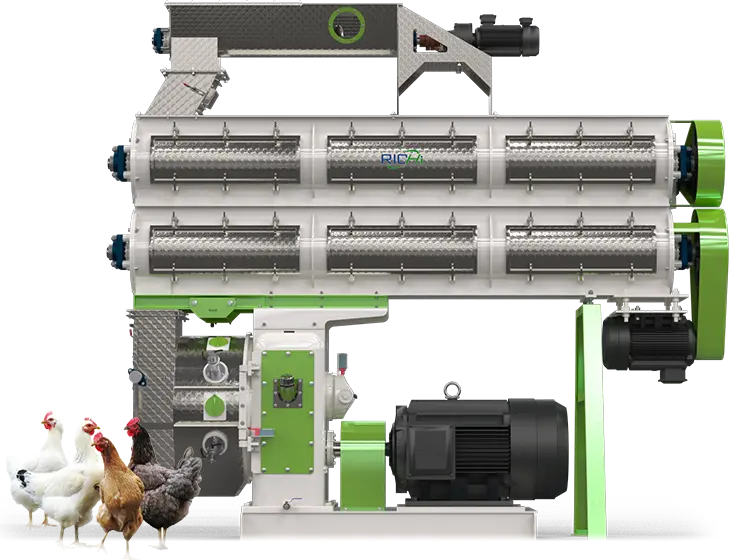

poultry feed machine for sale

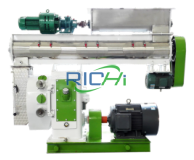

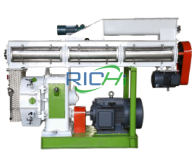

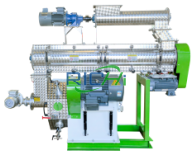

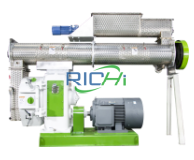

The poultry feed machine is core equipment directly affecting pellet quality. Different poultry types have varying feeding habits, growth stages, and nutritional needs, requiring different pellet sizes, hardness, and formulas. Pellet machines for chickens, turkeys, ducks, geese, and quail each have distinct configurations and parameters. Below, we introduce the main characteristics to help you choose the right equipment.

Different models of poultry feed making machine

SZLH250 poultry feed pellet machine

An entry-level small pelletizer, suitable for start-up small farms or family farms. The poultry feed machine is compact, requires little space; one or two people can easily operate it.

Main motor power (kW):22

Production capacity (T/H):1-1.5

SZLH320 poultry feed pellet machine

An economical and practical machine, popular for small farms. Many customers start here and upgrade later as their business grows.

Main motor power (kW):37

Production capacity (T/H):3-4

SZLH350 poultry pellet making machine

An ideal choice for transitioning to medium-sized farms. If your farm continues expanding, this model serves as a solid long-term investment.

Main motor power (kW):55

Production capacity (T/H):5-6

SZLH420 poultry feed maker machine

Many customers engaged in commercial farming choose this model, as it meets their own needs and allows them to sell some feed to supplement their income.

Main motor power (kW):110

Production capacity (T/H):10-12

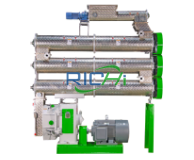

SZLH508 poultry feed pellet mill

Standard equipment for large-scale farms or small feed mills. Reinforced design enables continuous long-term operation under high intensity.

Main motor power (kW):160

Production capacity (T/H):15-16

SZLH558 poultry feed pelletizer

High-capacity poultry feed machine for large-scale production. High output, efficiency, and stable operation suit large farms or professional processing plants.

Main motor power (kW):185

Production capacity (T/H):20-22

SZLH678 poultry feed pellet mill

Core equipment in commercial feed production lines. Industrial-grade output, suitable for professional feed mills or ultra-large-scale farms.

Main motor power (kW):250

Production capacity (T/H):30-33

SZLH768 poultry feed pelletizer

Our largest poultry feed equipment model. Designed for large-scale enterprises with strong output and high automation.Need even higher output? We can customize!

Main motor power (kW):315

Production capacity (T/H):38-40

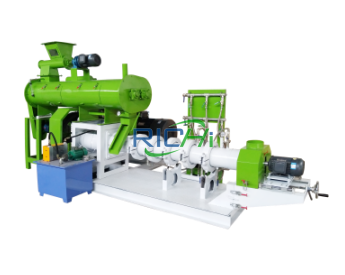

Poultry feed extruder

The poultry feed extrusion machine is designed for specialty poultry including birds, quails, pigeons, and other small avian species, creating softer, digestible feed ideal for smaller beaks.

Screw diameter (mm):90-225

Production capacity (T/H):0.5-3.0

Choosing the Right poultry feed machine for You

Every RICHI machine undergoes rigorous testing to ensure stability, durability, and a high return on investment. Want to know which model is best suited for your farm size and production needs? Contact us and let our professional team recommend the most suitable solution for you.

Complete solutions for poultry feed production line

Poultry Feed machine Project Video

The following case studies demonstrate the real-world performance of our poultry feed machine in daily production. From raw material feeding to finished product packaging, you can see the complete production process and equipment operation. If you would like to learn more about equipment configurations that best suit your farm size and budget, please feel free to contact our technical team for detailed quotations and project recommendations.

Poultry feed machine customer site projects

RICHI Machinery is a professional manufacturer specializing in various feed equipment, with over 30 years of experience. We have project cases in more than 140 countries worldwide and have received numerous repeat orders and positive feedback from our customers, which has allowed us to achieve such great success in the poultry feed machine field. As our slogan says, “Choose RICHI, you will be rich.” Your trust in us is always our driving force. If you are also looking for a satisfactory feed equipment manufacturer, some of our real-world projects below should be of great help to you.

Customer feedback and positive reviews

★★★★★

RICHI’s engineers designed the production process entirely according to my requirements and actual conditions.We are very satisfied.

Australia | Mr. Thompson

★★★★★

RICHI’s poultry feed production equipment maintains excellent performance even in high-temperature environments. This is a key reason why we chose this production line.

Saudi Arabia | Mr. Al-Faisal

★★★★★

This production line has helped us achieve self-sufficiency in feed production, greatly reducing breeding costs and significantly contributing to the development of local poultry farming.

Uganda | Mr. Paul

★★★★★

We purchased RICHI’s SZLH350 chicken feed pellet mill. The chicken feed pellets produced by this equipment have almost no dust, the pellets are very compact.

Spain | Mr. Martinez

★★★★★

We purchased a highly automated, well-structured poultry feed production line that fully meets our industrial feed production requirements. RICHI’s engineers provided perfect workshop solutions.

USA | Mr. Johnson

★★★★★

We highly value after-sales support, and this supplier demonstrated professionalism in technical communication and problem-solving.

Thailand | Mr. Somchai

★★★★★

The poultry feed machine equipment designed and manufactured by RICHI can handle a variety of local raw materials, significantly reducing our raw material costs. We plan to expand production within the next three years and will still choose RICHI.

Ethiopia | Mr. Dawit

★★★★★

After airport pickup by RICHI staff, I visited their factory. They have two large facilities with over 500 finished machines. The pellets had good appearance, low powdering rate, and excellent results!

Philippines | Mr. Reyes

★★★★★

The poultry feed machine is highly automated, enabling computer-controlled ingredient mixing, etc., requiring almost no manual labor for production, significantly improving the overall efficiency of our feed mill.

Malaysia | Mr. Lim

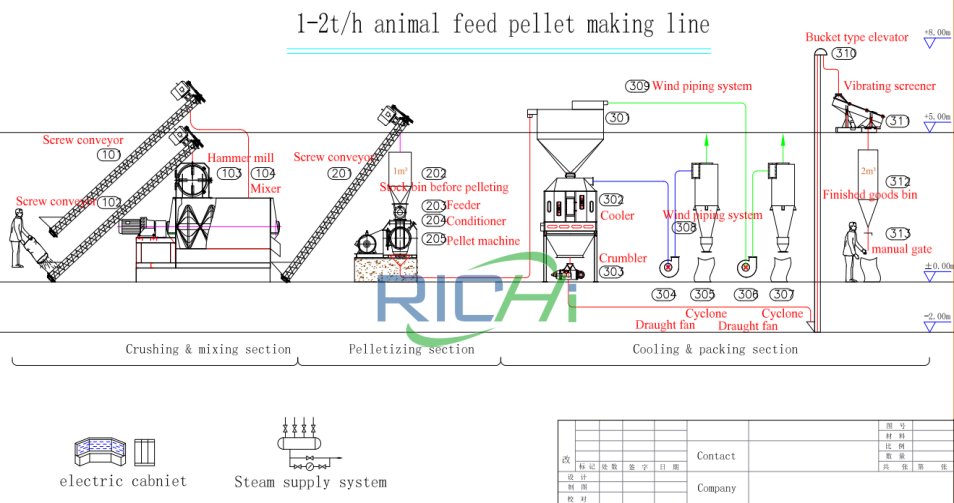

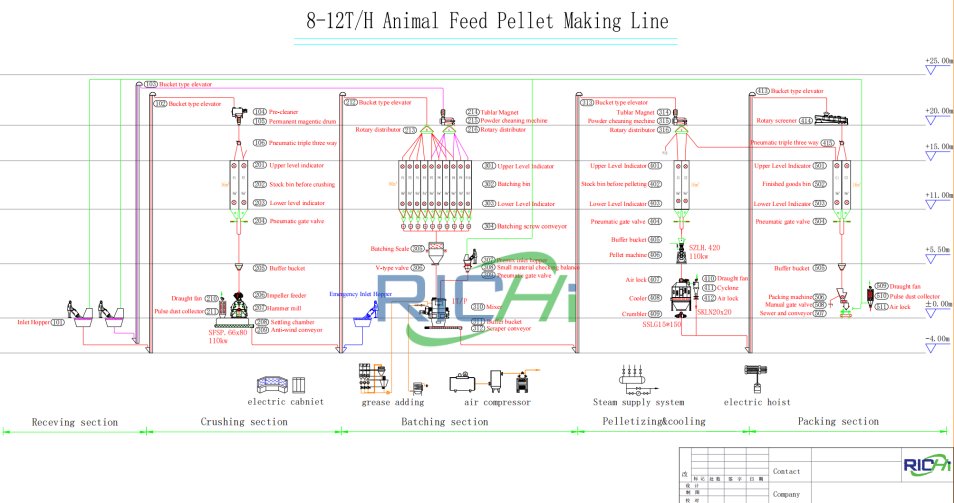

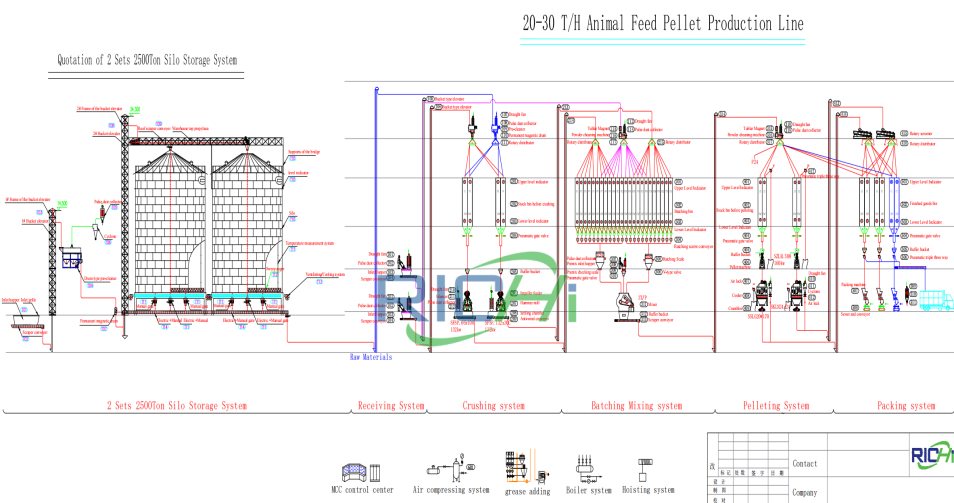

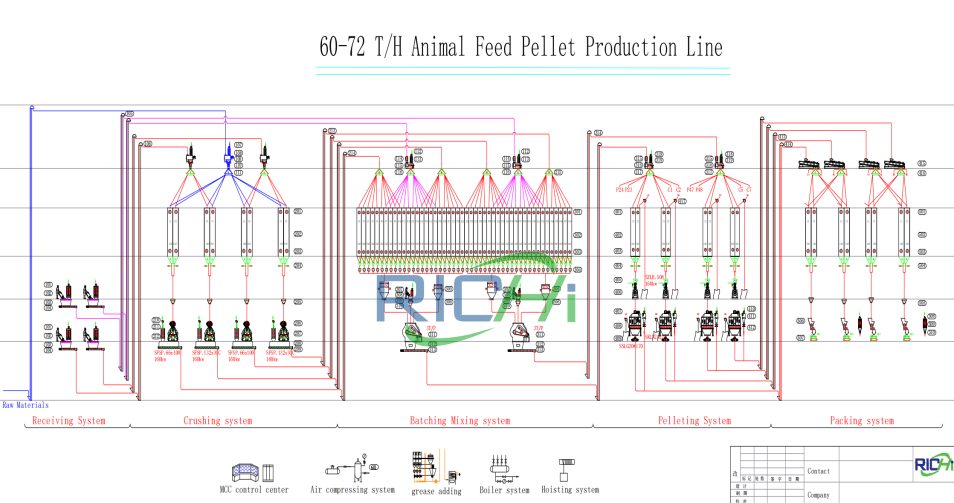

Production process flow chart for poultry feed machine

Customized Poultry Feed Production Solutions

We provide customized poultry feed lines from 1–2 T/H to 60–72 T/H, ensuring poultry feed machine matches production goals perfectly.

Multi-Animal Compound Feed Production Lines

The same line handles feed formulations for various animals including poultry and livestock, enabling flexible switching and large-scale compound feed production.

High-Configuration & Fully Automatic Feed Line Options

We offer high-configuration or fully automated solutions for stable, efficient, labor-saving production from raw materials to finished packaging.

Core Equipment Replacement & Feed Line Optimization

We support replacing core poultry feed machine like pellet mills in existing lines and provide systematic upgrades and process optimization.

Complete poultry feed production line process

To help you fully understand the poultry feed production process, we have compiled a complete production flow chart based on a poultry feed machine system, covering every step from raw material receiving, crushing, mixing, and pelletizing, to cooling, screening, and packaging. This process allows you to visually understand the function and equipment configuration of each stage, helping you plan or upgrade your poultry feed production line.

Poultry Feed Production Process Flow Chart

The flow chart below clearly illustrates each stage of the poultry feed production line. From raw materials to finished products, every step is visually presented, showing the continuous operation of the entire production line.

1、Receiving & Storage

2、Raw Material Cleaning

3、Crushing / Grinding Section

4、Batching & Weighing

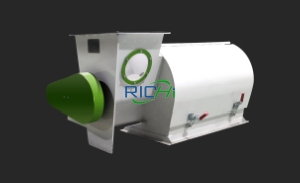

5、Mixing Section

6、Pelletizing Section

7、Cooling Section

8、Screening Section

9、Crumbling (Optional)

10、Packing & Storage

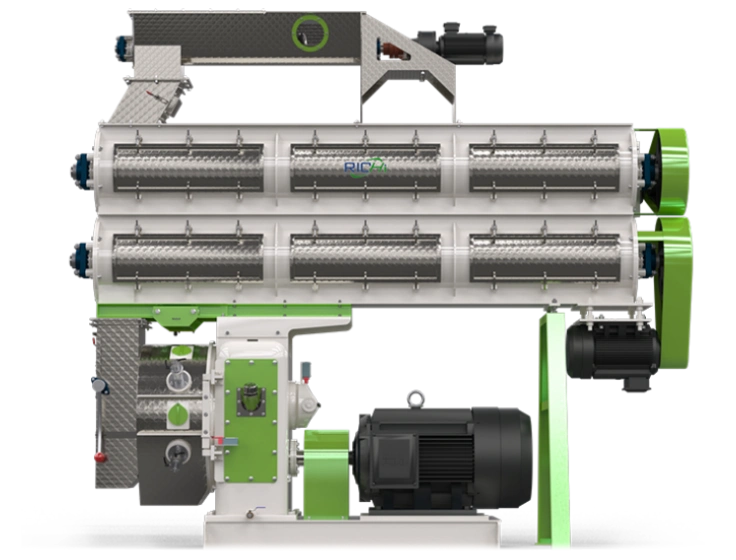

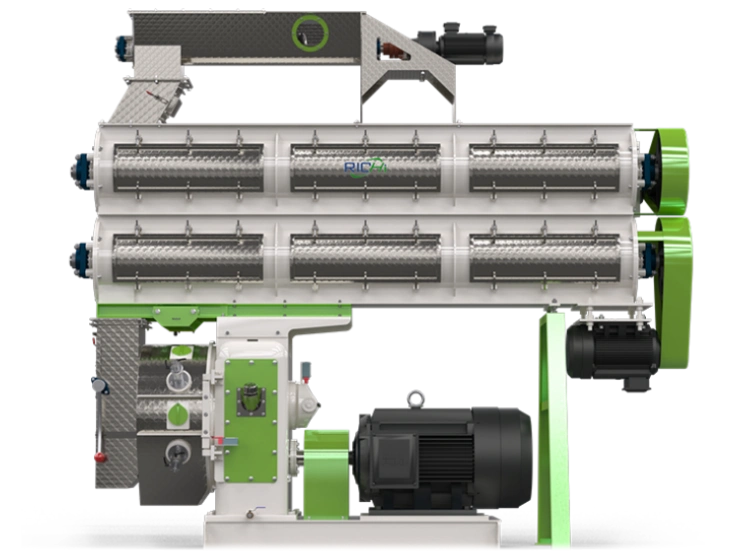

Poultry Feed Production Equipment Showcase

Here, you can see various core equipment used in the entire production line, including crushers, mixers, ring die poultry feed pellet mills, coolers, and packaging machines. Each piece of equipment is meticulously designed to provide reliable support for your feed processing business.

Poultry Feed Crusher

Poultry Feed Mixer

Poultry feed pellet machine

Feed Pellet Cooler

Receiving & Storage Silo

Powder Cleaning Screen

batching scale

Rotary Feed Screen

Oil Addition Equipment

Poultry Feed Crumbler

Belt Conveyor

feed packaging machine

Build your efficient poultry feed production line with our customized, fully automated solutions—stable, high-quality, and ready to boost your production. Contact us today!

Global Poultry Feed Market Outlook

As people’s living standards continue to improve globally, the demand for animal protein is also rising. Poultry, due to its short production cycle and low cost, has become the main source of protein. This has directly driven the rapid development of the poultry feed market. However, the situation varies greatly across continents. Let’s take a closer look at the development prospects of each continent.

Asia

1

Asia boasts the largest and fastest-growing market. Rising incomes drive meat consumption growth. Small-scale farming declines as large operations expand.

- India: Over one billion population with rising egg and chicken consumption, expanding middle class, and huge market potential.

Africa

2

The African poultry feed market will expand rapidly due to population growth and urbanization. By 2030, poultry production is expected to double.

- South Africa: Africa’s most economically developed market, with relatively advanced farming technology and a stable demand for high-quality feed.

Europe

3

The European market features strict regulations and high standards. Feed safety, traceability, and environmental requirements are extremely stringent globally.

- France: Annual chicken production exceeds 1.5 million tons with stable demand for feed meeting EU standards.

North America

4

North America is highly mature and intensive, requiring automated poultry feed machine. Competition focuses on innovation: functional feed and precision nutrition.

- United States: Annual feed production exceeds 180 million tons. Antibiotic-free and organic feed demand increasing, organic poultry market growing over 10% annually.

South America

5

South America is a major chicken export base with abundant resources. High corn and soybean yields with low costs make poultry highly competitive internationally.

- Brazil: World’s largest chicken exporter with annual exports exceeding 4.5 million tons, over one-third of global exports.

Oceania

6

Oceania has abundant land and excellent farming environment, targeting high-end markets. Exports focus on premium poultry to Asia.

- Australia: Its poultry industry is highly modernized, emphasizing animal welfare and environmental protection. Market receptive to innovative products and new technologies.

Frequently Asked Questions

Is this machine complicated to operate? Can our inexperienced workers learn it?

+

It’s not complicated at all. Modern equipment is designed to be very user-friendly; it’s basically just pressing buttons and adjusting parameters. Generally, a one-day training period is enough for workers to operate it independently.

We will provide a detailed operation manual and video tutorials. Upon delivery, we will also arrange for technicians to train your workers, providing hands-on instruction until they can operate it correctly. Moreover, many operating interfaces are touchscreens, making the display very intuitive; any problems are immediately apparent.

How long will the machine last? Will it break down frequently?

+

Under normal use, the main unit should last 10-15 years without problems. Of course, this assumes proper maintenance and timely replacement of necessary parts. If you would like to see a video of our poultry feed machine, which has been running for over ten years, please contact us.

Consumable parts like molds and hammers may need replacement every six months to a year, depending on the intensity of use. However, these are consumables, inexpensive, and easy to replace.

Our equipment is made with high-quality materials, and key components like gearboxes and motors are sourced from reputable brands, ensuring quality. As long as there is no improper operation or inadequate maintenance, major malfunctions are rare.

Can you produce different types of feed? For example, chicken feed, duck feed?

+

Absolutely. We can produce feed for any poultry, including chickens, ducks, geese, and quails.

The main difference between different poultry feeds is the formula and the proportion of raw materials. The machine only needs to adjust the size of the mold holes to produce different sizes of pellets. For example, small pellets for chicks and large pellets for adult chickens.

Changing the formula is also simple; just clean the feed hopper and mixer, replace the raw materials, and it’s done in about ten minutes. Many customers use the same equipment to produce different feeds in rotation.

Can I see samples or visit the factory first?

+

Of course! We warmly welcome customers to visit our factory.

You can see our production workshop and testing equipment, and you can also bring your raw materials, and we will make samples for you on-site to see the effect.

If it is inconvenient for you to come, we can also send samples to you, or we can connect via video to show you the factory and the equipment in operation. Many customers decide to cooperate after seeing samples or visiting the factory.

We are confident in our products, so we welcome your inspection and comparison. Seeing is believing; you can only be at ease after seeing it for yourself. You can find us on YouTube.

Do you provide after-sales service? What if the machine breaks down?

+

Of course! We have a comprehensive after-sales service system.

First, the poultry feed machine is guaranteed for one year, and we are responsible for any quality problems during this period. After the warranty period, we also provide lifetime technical support.

If the machine has a problem, please contact us first. 80% of minor problems can be resolved via video call. If it cannot be resolved, we will arrange for a technician to come to your location or send parts by express delivery.

We have common spare parts in stock, and delivery is fast. We also suggest that customers keep some spare parts on hand, so that if replacement is needed, there will be no waiting and production will not be delayed.

About richi machinery

RICHI Machinery is a professional manufacturer specializing in the research, development, production, and sales of poultry feed machine and equipment, with over 30 years of experience in the poultry feed equipment industry. We have always adhered to the principle: focus on product quality and customer service, and business will naturally follow. Step by step, we have sold our products to over 140 countries worldwide, gradually building our reputation and experience. Customers who find our equipment satisfactory recommend us to others. Because we have encountered diverse needs and situations, we truly understand the pain points of different customers and can provide the most suitable solutions.

30+

years

Experience

140+

Export Countries

80000+

㎡

Factory Area

1000+

Projects

If you are planning or upgrading your poultry feed project, please feel free to contact us. RICHI Machinery will provide you with professional solutions truly tailored to your needs.

Our Core Services

Free Project Consultation

Unsure what equipment you need or how much investment is required? Our sales representative will discuss your needs in detail, and our engineers will provide professional advice based on your production requirements, site size, and budget.

Customized Planning Solutions

Based on your specific needs, we create detailed project planning solutions, including equipment configuration, workshop layout, and process flow to ensure optimal production efficiency.

On-site Installation and Commissioning

Upon equipment shipment, our technical engineers visit your factory to oversee installation, commissioning, and trial operation, ensuring each piece operates correctly and the entire line runs smoothly.

Professional Personnel Training

We provide systematic operator training covering operating procedures, parameter adjustments, and daily maintenance. Free operation manuals and video tutorials are included with every project.

Warranty and Repair Service

All equipment includes a one-year warranty. We provide free repair or replacement for quality issues within warranty and offer lifetime after-sales service to resolve problems promptly.

Online Technical Support

Our technical team is available 24/7 via phone, WhatsApp, and email. Our after-sales personnel conduct regular follow-ups to provide maintenance advice and support.

Fast Spare Parts Supply

We maintain ample stock of commonly used and easily damaged parts at competitive prices. Orders ship quickly, and in emergencies, spare parts can be airlifted.

Equipment Upgrades and Retrofits

We provide upgrade and retrofit services including automated control upgrades, capacity increases, and technological improvements. We promptly notify existing customers of any new technologies we develop.