Livestock Feed Machine

A professional supplier of livestock feed machine, we manufacture cattle, pig, and sheep feed, offering everything from single pellet mills to complete production lines. Our equipment is durable and easy to operate, helping you maintain firm control over feed quality and costs.

Turnkey Livestock Feed Machine Equipment Solution

cattle feed machine

Cow feed machine

pig feed machine

horse feed machine

sheep feed machine

goat hen feed machine

rabbit feed machine

camel feed machine

What type of livestock feed do you need?

Those who raise livestock know that different animals have completely different dietary habits. Some animals are purely herbivores, eating only forage and grains; some need a mixture of grains and forage; and others require protein supplements.

This is why choosing the right livestock feed machine is crucial, as different feed formulations require different processing equipment and configurations.

Different Animal Different Livestock Feed Machine

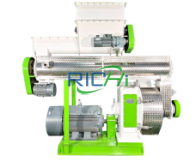

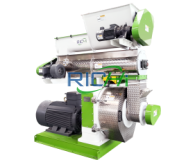

Different models of livestock feed making machine

RICHI has specially developed the CZLH series livestock feed making machine, specifically designed to process various crop straws (corn stalks, wheat straw, rice straw, etc.), forage grasses (alfalfa, timothy grass, ryegrass, etc.), and other high-fiber raw materials such as rice husks. You might ask: Isn’t a regular pellet mill sufficient? Not really. Straw and forage have extremely high fiber content and strong toughness, which ordinary pellet mills simply cannot handle.

CZLH320 livestock feed pellet machine

- Output: 0.5-0.6 tons/hour

- Main Motor Power: 22 kW

- Arch-breaking Feeder: 2.2 kW

- Forced Feeder: 0.75 kW

- Ring Die Inner Diameter: 320mm

- Pellet Diameter: 4-12mm

CZLH350 livestock pellet machine

- Output: 1.0-1.2 tons/hour

- Main Motor Power: 37 kW

- Arch-breaking Feeder: 2.2 kW

- Forced Feeder: 0.75 kW

- Ring Die Inner Diameter: 350mm

- Pellet Diameter: 4-12mm

CZLH420 livestock feed machine

- Output: 1.8-2.0 tons/hour

- Main Motor Power: 90 kW

- Arch-Breaking Feeder: 3 kW

- Forced Feeder: 1.5 kW

- Ring Die Inner Diameter: 420mm

- Pellet Diameter: 4-12mm

CZLH520 livestock pellet maker

- Output: 2.8-3.0 tons/hour

- Main Motor Power: 132 kW

- Arch-breaking Feeder: 3 kW

- Forced Feeder: 1.5 kW

- Ring Die Inner Diameter: 520mm

- Pellet Diameter: 4-12mm

CZLH678 livestock pellet maker

- Output: 4-5 tons/hour

- Main Motor Power: 185 kW

- Arch-Breaking Feeder: 3 kW

- Forced Feeder: 1.5 kW

- Ring Die Inner Diameter: 673 mm

- Pellet Diameter: 4-12 mm

CZLH768 livestock feed pellet machine

- Output: 6-8 tons/hour

- Main Motor Power: 250 kW

- Arch-Breaking Feeder: 4 kW

- Forced Feeder: 1.5 kW

- Ring Die Inner Diameter: 762 mm

- Pellet Diameter: 4-12 mm

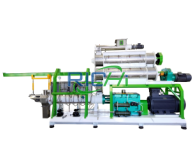

Livestock feed extruder

For customers with unique processing needs or special feed formulations, RICHI offers customized livestock feed extruders. Some feed manufactures have specific processing techniques that require the production of specialty feeds that traditional pellet mills cannot handle.

Our engineering team designs customized extruder systems based on your raw materials and production requirements, including barrel temperature, screw configuration, and die specifications.

Choosing the Right livestock feed making machine for You

Every RICHI livestock feed machine undergoes rigorous testing to ensure stability, durability, and a high return on investment. Want to know which model is best suited for your farm size and production needs? Contact us and let our professional team recommend the most suitable solution for you.

Complete solutions for livestock feed production

The livestock feed pellet mill is the core equipment, but stable production requires a complete system with properly matched components. RICHI provides both individual livestock feed machines and customized complete production line solutions tailored to your raw materials, capacity, site, and budget. Our technical team supports you from process design to equipment configuration, ensuring a practical, reliable solution for long-term stable operation.

Real Livestock Feed Machine Projects Worldwide

These two real-world project videos provide a direct understanding of the practical application and effectiveness of livestock feed machines in ranches worldwide. From reducing feed costs to improving production efficiency, they demonstrate the long-term value that the equipment brings to ranches.

Livestock Feed Machine for sale Global

Every farm faces its own challenges—capacity, cost, space, and raw materials. Looking at how these customers solved their specific problems with the right livestock feed machine might offer some inspiration.

Customer feedback and positive reviews

★★★★★

We’ve been using RICHI livestock feed machine on our cattle farm for 3 years, and the quality is excellent. We compared several companies before choosing RICHI because of their professionalism.

John Smith – USA

★★★★★

I started with small equipment, initially buying the CZLH250. After two years, my business grew, so I bought the CZLH420. RICHI’s equipment is truly high-quality, and the price is fair.

Rajiv Patel – India

★★★★★

In Egypt, feed is the biggest cost in sheep farming. After buying RICHI’s 5-ton/hour production line, we can mix our own feed, reducing costs by more than 40%.

Mohammed Ali – Egypt

★★★★★

The South African feed market is highly competitive, but our products are very popular. This is all thanks to RICHI’s feed equipment, which produces clean and uniform pellets, and our customers are very satisfied.

Peter Van den Berg – South Africa

★★★★★

We are a large pig farm and have very high demands on equipment. RICHI’s equipment has strong production capacity and good stability, and most importantly, the after-sales service is exceptional.

Maria Santos – Brazil

★★★★★

Sheep farming is common in Ireland, but most people still buy feed. I decided to make my own and bought RICHI equipment. Now I not only use it myself but also sell it to surrounding farmers.

James O’Connor – Ireland

Livestock Feed Production Line Process Flowchart

Project Consulting & Solution Customization

Equipment Manufacturing & Quality Assurance

Installation, Commissioning, and Personnel Training

Long-Term Technical Support & Spare Parts Service

Contact us now to get a tailored solution, competitive pricing, and professional support for your feed project.

Complete livestock feed production line process

Some clients ask: Is the livestock feed production process very complicated? Actually, the process is quite clear. A modern livestock feed production line simply mechanizes and automates the traditional manual feed production steps. Below, we’ll use the most intuitive method to guide you through the complete livestock feed production process, so you clearly understand how a production line operates after you invest in it.

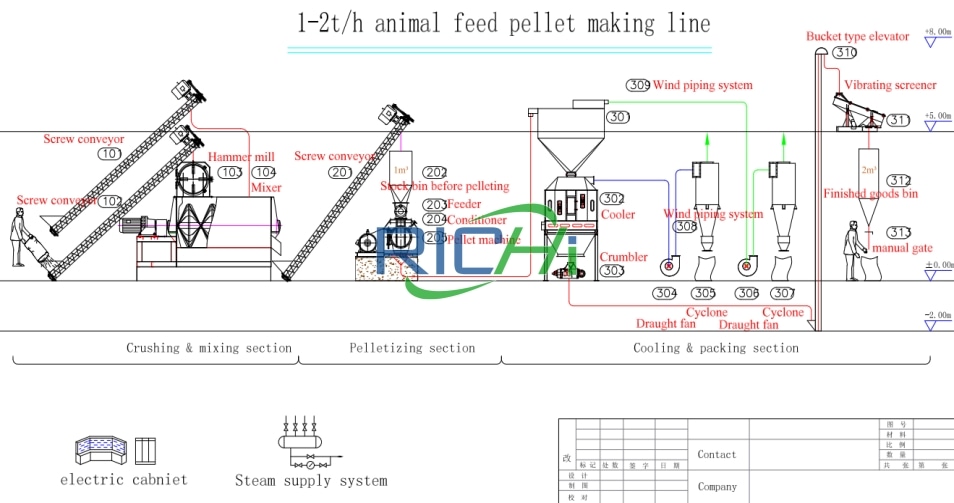

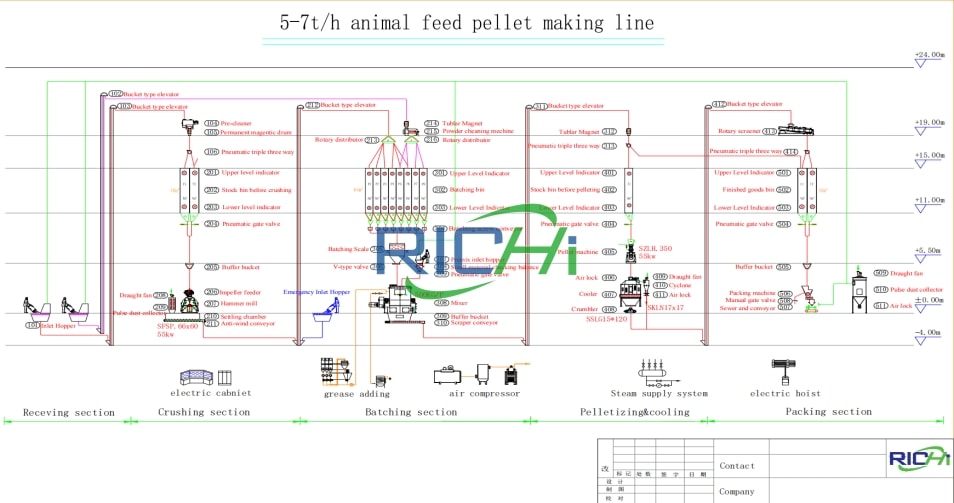

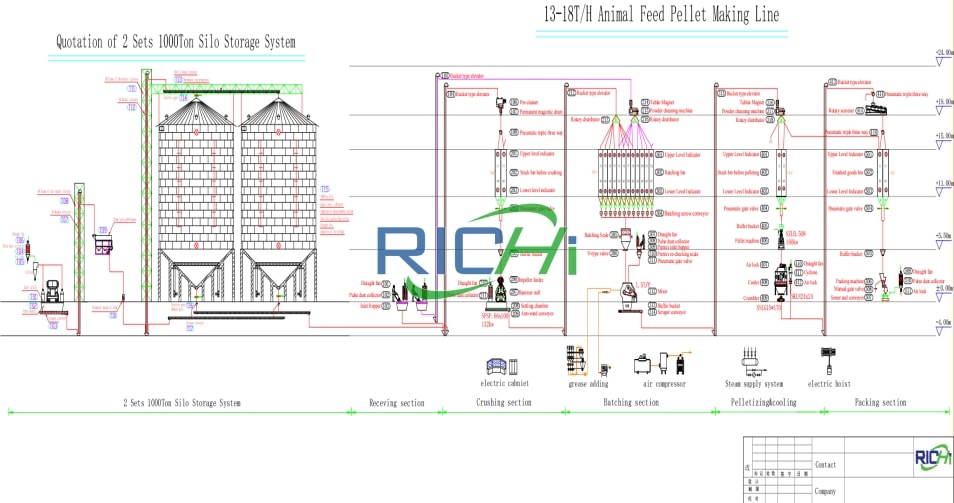

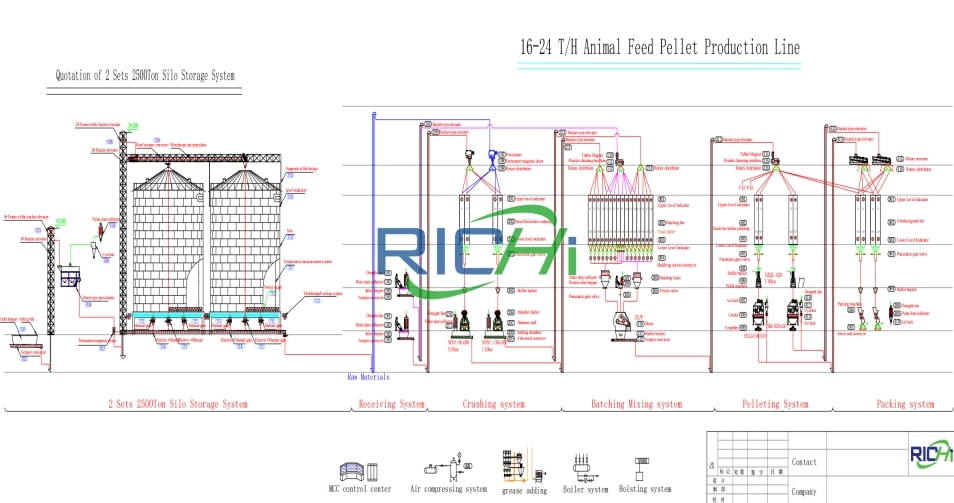

Livestock Feed Production Process Flow Chart

Below is a standard livestock feed production line process flow, clearly showing from left to right how materials are transformed into finished pelleted feed step by step. The core process is basically the same for production lines of different production scales; only the equipment models and levels of automation differ.

1、Reception and Storage

2、Cleaning and Removal

3、Crushing and Grinding

4、Batching and Weighing

5、Mixing and Blending

6、Pelleting and Forming

7、Pellet Cooling Process

8、Pellet Drying Process

9、Screening and Grading

10、Coating and Packaging

Livestock Feed Production Equipment Showcase

The flowchart provides an overview of the production process, but here we show all the livestock feed machines used in the livestock feed production line—from receiving to packaging—allowing you to see precisely all the equipment that makes up a complete livestock feed production system.

Livestock Feed Crusher

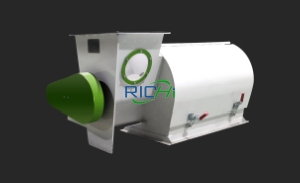

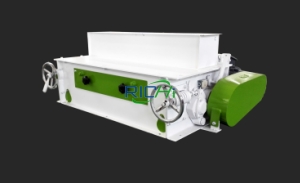

Livestock Feed Mixer

Livestock feed pellet maker

Feed Pellet Cooler

Receiving & Storage Silo

Powder Cleaning Screen

batching scale

Rotary Feed Screen

Forage/Grass crusher

Oil Addition Equipment

Livestock Feed Crumbler

Vacuum coating equipment

Belt Conveyor

U-shaped scraper conveyor

Screw conveyor

feed packaging machine

If you are considering building a new livestock feed production line or upgrading an existing one, feel free to contact us. Our team can help you evaluate your raw materials, capacity needs, and site conditions to recommend a practical and efficient solution.

Future Market Prospects for Livestock Feed

The livestock feed machine industry is currently entering a new stage of development. Global demand for meat and protein is constantly increasing, and farming methods in various countries are also upgrading. From the expanding scale of farming in Asia to the higher requirements for feed nutrition formulation and production precision in North America, different regions have their own opportunities.

Asia

1

The World’s Largest and Fastest Growing Market

Asia accounts for over 35% of global feed production, with an annual output exceeding 400 million tons, and continues to grow at an average annual rate of 3-5%.

Africa

2

A High-Potential Emerging Market

Africa is currently one of the fastest-growing regions in the feed industry, but the adoption rate of industrialized feed remains low, indicating a very large overall market potential.

Europe

3

Strict Regulations, Highly Standardized Market

Europe’s feed production is approximately 200 million tons. The market is mature and regulated. Strict regulations mean high barriers to entry, but once entered, it’s a market worth cultivating.

North America

4

Highest Scale and Largest Demand

North America’s annual production remains stable at over 200 million tons, with the USA dominating.

South America

5

Abundant Feed Raw Material Resources

South America is a major global producer of corn and soybean meal. The feed industry is rapidly upgrading towards large-scale and industrialized production, resulting in very rapid market growth.

Oceania

6

Specialized and Export-Oriented Market

While not the largest market, Oceania boasts high specialization and mature customers with strong acceptance of quality feed and livestock feed machine, catering to local and export markets.

Frequently Asked Questions

I have no experience in animal feed production. Can I learn to operate this equipment?

+

Absolutely! Our livestock feed machine is actually quite simple to operate, and we provide comprehensive training and support.

1、Pre-sales Guidance:

- Free Formula Consultation: We have a team of nutritionists who can design feed formulas for you based on your animal species.

- Raw Material Suggestions: We’ll tell you which raw materials are suitable in your area, how to select them, and how to store them.

- Production Process Explanation: We’ll explain the entire production process in detail so you have a clear understanding.

2、In-sales Training:

- During installation and commissioning, our engineers will provide hands-on training to your workers on-site.

- Training content includes: equipment operation, parameter adjustment, daily maintenance, and troubleshooting common problems.

- Training time is 3-7 days, until your team fully masters the skills.

3、After-sales Support:

- Detailed operation manuals and video tutorials

- 24-hour technical hotline to answer questions anytime

- Remote video guidance; most problems can be solved remotely

- Regular follow-ups to understand production status and provide improvement suggestions.

Many customers started with no experience, beginning from scratch. After our training and guidance, they are now very successful. Some customers have even learned techniques from us and gone on to instruct others, becoming local “experts.”

What are the differences in livestock feed machine requirements between making cattle/sheep feed and making pig/chicken feed?

+

The main difference lies in the required pellet diameter and hardness. Ruminants like cattle and sheep require coarser pellets (6-8 mm in diameter) because their digestive systems are suited to chewing larger particles; pig feed typically uses 4-6 mm pellets, while chicken feed requires finer pellets (2-4 mm).

In addition, cattle and sheep feed contains more crude fiber (such as straw and hay powder), requiring more powerful motors and more wear-resistant molds; pig and chicken feed is mainly concentrate, which is relatively easy to press. Pig feed, in particular, usually contains premixes (containing vitamins, trace elements, amino acids, etc.), and these premixes have fine components, requiring high uniformity in mixing.

When producing pig feed containing premixes, it is recommended to use a twin-shaft paddle mixer, with a mixing time of at least 8-10 minutes to ensure the premix is evenly distributed in the whole feed, avoiding nutritional deficiencies in some pigs due to uneven mixing. Furthermore, the pelleting temperature should not be too high, as high temperatures can destroy the vitamin activity in the premix.

If you need to produce multiple feeds, it is recommended to choose a model with interchangeable dies of different aperture sizes, so that one machine can meet different needs. Equipping yourself with a high-quality mixer is especially important for producing concentrate-type feeds like pigs and chickens.

Can a livestock feed pellet mill be used to produce feed for different animals?

+

Absolutely! Our feed pellet mill is a universal machine that can produce feed for various livestock or ruminants, including cattle, sheep, pigs, horses, rabbits, and camels.

How does a livestock feed pellet mill produce feed for multiple animals simultaneously?

- Changing the die: Different animals require different pellet sizes; simply change the die with a different aperture. For example, use a 6-8mm die for cattle feed and a 2-4mm die for rabbit feed.

- Adjusting the formula: Different animals have different nutritional needs; adjust the raw material formula. The equipment doesn’t need to be changed, only the formula.

- Flexible production: Produce pig feed in the morning, and in the afternoon, change the die and formula to produce sheep feed—very flexible.

Many customers use one machine to produce multiple feeds, meeting the needs of their different animals and also allowing them to sell various products externally, expanding their market.

How long can the produced feed pellets be stored? What storage conditions are required?

+

Normally produced feed pellets can be stored for 3-6 months under appropriate conditions. The key is to control moisture and temperature:

- Pelletizers must be cooled after exiting the machine, and only bagged when the temperature is within 5 degrees Celsius above room temperature; otherwise, they will mold and spoil due to heat buildup.

- Moisture content should be controlled below 12%; exceeding 13% easily leads to mold growth.

- The storage environment should be dry and well-ventilated, ideally with a temperature below 25 degrees Celsius and a relative humidity not exceeding 65%.

In hot and humid summer areas, it is recommended to use the pellets immediately after production and store them for no more than one month. In dry winter areas, they can be stored for longer. When using woven bags for packaging, use pallets to keep them off the ground; do not stack them against walls, and leave ventilation gaps between each pile. Feed with added oil is prone to oxidation, which will shorten its shelf life.

About richi machinery

RICHI Machinery is a professional manufacturer specializing in the research, development, production, and sales of feed machinery and equipment, with over 30 years of experience in the livestock feed machine industry. We have always adhered to the principle: focus on product quality and customer service, and business will naturally follow. Step by step, we have sold our products to over 140 countries worldwide, gradually building our reputation and experience. Customers who find our equipment satisfactory recommend us to others. Because we have encountered diverse needs and situations, we truly understand the pain points of different customers and can provide the most suitable solutions.

30+

years

Experience

140+

Export Countries

80000+

㎡

Factory Area

1000+

Projects

If you are planning or upgrading your livestock feed project, please feel free to contact us. RICHI Machinery will provide you with professional solutions truly tailored to your needs.

Our Core Services

Free Project Consultation

Customized Planning Solutions

On-site Installation and Commissioning

Complete Personnel Training

Warranty and Repair Services

Online Technical Support

Fast Spare Parts Supply