Biomass pellet production has emerged as a cornerstone in the renewable energy sector, addressing the growing need for sustainable and eco-friendly energy solutions. Biomass pellets, often derived from wood, agricultural residues, and other organic materials, offer a viable alternative to traditional fossil fuels. Their combustion efficiency, reduced carbon footprint, and accessibility make them an attractive energy source, contributing significantly to environmental sustainability.

The importance of biomass pellet production extends beyond environmental benefits. As global energy demands rise, the need for diversified and renewable energy sources becomes paramount. Biomass pellets play a critical role in mitigating the reliance on non-renewable energies, thereby enhancing energy security and reducing greenhouse gas emissions.

The versatility of biomass pellets means they can be used in various applications, from heating systems to large-scale industrial processes, further underlining their significance in the modern energy landscape.

The escalating demand for biomass pellets is driven by numerous factors, including government regulations promoting renewable energy, advancements in biomass technology, and a growing awareness of environmental sustainability.

As such, businesses are increasingly venturing into the biomass pellet production industry, recognizing the lucrative opportunities it presents. However, success in this sector hinges on several factors, with the choice of a biomass pellet production line manufacturer being one of the most critical.

Selecting the right manufacturer for a biomass pellet production line is crucial for ensuring operational efficiency, product quality, and long-term viability. The manufacturer’s expertise, technological capabilities, and support services can profoundly impact the performance and profitability of the production line.

Therefore, businesses must undertake thorough due diligence when choosing a manufacturer, considering aspects such as machine quality, innovation, customer support, and total cost of ownership. A well-informed decision can pave the way for a successful venture in the biomass pellet production industry, aligning with environmental goals and market demands.

Key Criteria for Choosing a Biomass Pellet Production Line Manufacturer

Selecting a reliable biomass pellet production line manufacturer is crucial for ensuring a productive and efficient production line. Several key factors must be meticulously considered to make an informed decision.

Experience: One of the primary factors to evaluate is the manufacturer’s experience in the industry. A company with extensive experience is likely to have a deep understanding of the nuances involved in biomass pellet production. This experience translates into expertise, reliability, and the ability to anticipate and solve potential challenges that may arise during the production process.

Technological Innovation: In the rapidly evolving field of biomass pellet production, staying ahead of technological trends is essential. Manufacturers who invest in the latest technology and demonstrate a commitment to innovation are better equipped to offer high-efficiency, cutting-edge production lines. Advanced technology not only boosts productivity but also enhances the quality of the biomass pellets produced.

Customer Support: Robust customer support is indispensable. From the installation phase to ongoing maintenance and troubleshooting, a manufacturer that provides comprehensive and responsive support can significantly reduce downtime and operational disruptions. Ensure that the manufacturer has a well-established support system in place, including technical assistance and readily available replacement parts.

Warranty: A solid warranty is a testament to the manufacturer’s confidence in their product’s durability and performance. It is crucial to scrutinize the warranty terms, including coverage, duration, and any exclusions. A strong warranty offers peace of mind and assures that any issues will be addressed promptly and without additional costs.

Price: While cost is an important consideration, it should not be the sole decisive factor. Evaluating the price in relation to the value offered by the manufacturer is critical. A lower initial cost may be tempting, but it is vital to consider the long-term benefits of investing in a higher-quality production line that promises efficiency, longevity, and lower maintenance costs. Balance affordability with the quality and performance capabilities of the biomass pellet production line.

In conclusion, thoughtful consideration of these key criteria will guide you in selecting a reputable biomass pellet production line manufacturer, ensuring a seamless, efficient, and productive operation.

Specific Processes in a Biomass Pellet Production Line

A biomass pellet production line encompasses several critical stages, each contributing significantly to the overall efficiency and quality of the final product. Understanding these processes is essential when selecting a manufacturer to ensure the line’s optimal operation and output.

Raw Material Preparation

The initial stage involves preparing raw materials, which could include wood chips, agricultural residues, or other biomass sources. It’s crucial to source clean, uncontaminated materials to prevent impurities from compromising the quality of the pellets.

Size Reduction

Once prepared, the raw materials undergo size reduction. This process typically involves grinding or chipping to achieve a uniform particle size, which is vital for efficient drying and pelletizing. Consistent particle size ensures the pellets maintain structural integrity and burn uniformly.

Drying

The drying stage reduces the moisture content of the biomass to an optimal level, usually below 15%. Proper moisture control is fundamental as it impacts the pelletizing process and the combustion quality of the final pellets. Overly moist materials can hinder pellet formation, while overly dry materials can lead to unnecessary energy expenditure.

Pelletizing

Pelletizing is the core process where the prepared and dried biomass is compressed into pellets. This involves forcing the materials through a pellet mill or press, under high pressure and temperatures. The efficiency of this stage largely determines the quality of the finished pellets, including their density and combustion properties.

Cooling

Following pelletizing, the hot, newly formed pellets must be cooled. Cooling stabilizes the pellets, preventing them from becoming soft or breaking apart. Proper cooling preserves the structural integrity and hardness of the pellets, making them suitable for transportation and storage.

Screening

Post-cooling, the pellets undergo screening to remove fines and dust, ensuring uniformity and quality. High-quality pellets meet specific size and density metrics, which screening helps maintain by filtering out substandard particles.

Packaging

The final stage is packaging, where the pellets are bagged or stored in bulk. Proper packaging is essential to protect the pellets from moisture and physical damage during transportation and storage, ensuring the end-users receive a high-quality product ready for use.

Each of these stages plays a pivotal role in the biomass pellet production line, contributing to the operational efficiency and the quality of the final product. When evaluating manufacturers, it’s important to assess their expertise and technology in managing these processes to ensure reliable and high-quality pellet production.

Critical Points to Pay Attention to in Biomass Pellet Production

When operating a biomass pellet production line, several critical factors merit close attention to ensure both efficiency and the quality of the final product. One primary consideration is the quality of the raw material. High-quality, consistent raw materials are foundational to producing superior biomass pellets. It is imperative to source biomass feedstock that is free from contaminants and possesses uniform characteristics.

Another crucial element is monitoring the moisture content of the raw material. The ideal moisture content for biomass pellet production typically ranges between 10-20%. Exceeding this range can lead to inadequate pellet formation and increased energy consumption, while lower moisture levels can result in brittle pellets that degrade easily. Moisture content should therefore be meticulously adjusted and controlled throughout the production process.

Regular maintenance of machinery is essential for the smooth operation of a biomass pellet production line. Well-maintained equipment operates more efficiently and is less prone to unexpected breakdowns, which can halt production and incur significant costs. Implementing a routine maintenance schedule, conducting regular inspections, and promptly addressing any mechanical issues can greatly extend the lifespan of the production machinery.

Operational safety should be a paramount concern within any biomass pellet production facility. Adhering to stringent safety protocols and ensuring that all staff are adequately trained can mitigate the risk of accidents, thereby fostering a safer working environment. Proper ventilation, dust control measures, and appropriate use of protective gear are some of the best practices that contribute to operational safety.

To achieve consistent pellet quality and maximize production efficiency, best practices should be rigorously applied. These include calibrating machinery regularly, ensuring a balanced and controlled feedstock supply, and keeping abreast of technological advancements in the field.

By meticulously attending to these critical areas, a biomass pellet production line can operate at optimal efficiency, producing high-quality pellets that meet market demands.

Overview of RICHI Machinery

RICHI Machinery stands distinguished as the most professional pellet mill manufacturer in China, with a commanding presence particularly in Henan Province. Established with a mission to innovate and lead within the industry, the company has achieved a significant reputation for its advanced expertise and comprehensive biomass pellet production lines.

RICHI Machinery not only provides tailor-made solutions but also adheres to stringent quality standards that cater to a global clientele.

The company’s enduring legacy is underscored by its extensive history. Since its inception, RICHI Machinery has been dedicated to pioneering advancements in the biomass pellet production sector. This dedication is evident in their broad spectrum of machinery and equipment designed to convert raw materials into high-quality pellets efficiently and sustainably.

With a wide array of products, their portfolio includes different types of pellet mills, auxiliary machinery, and complete turnkey pellet production lines.

RICHI’s market presence is notable both domestically and internationally. Leveraging state-of-the-art technology and a well-established supply chain, the company has successfully penetrated markets not only across China but also in numerous countries worldwide.

This expansive reach is supported by their commitment to research and development, which ensures that their biomass pellet production lines remain at the forefront of technological innovation. Furthermore, the company’s comprehensive after-sales service and technical support provide customers with continuous, reliable assistance, reinforcing RICHI Machinery’s position as a trusted partner in the industry.

In addition to their technical prowess, RICHI Machinery’s commitment to sustainability and environmental responsibility distinguishes them within the market. Their biomass pellet production lines are designed to minimize energy consumption and optimize material utilization, aligning with global efforts to reduce carbon footprints and promote renewable energy sources.

Through a combination of expert knowledge, robust machinery, and eco-friendly practices, RICHI Machinery sets the standard for excellence in pellet manufacturing.

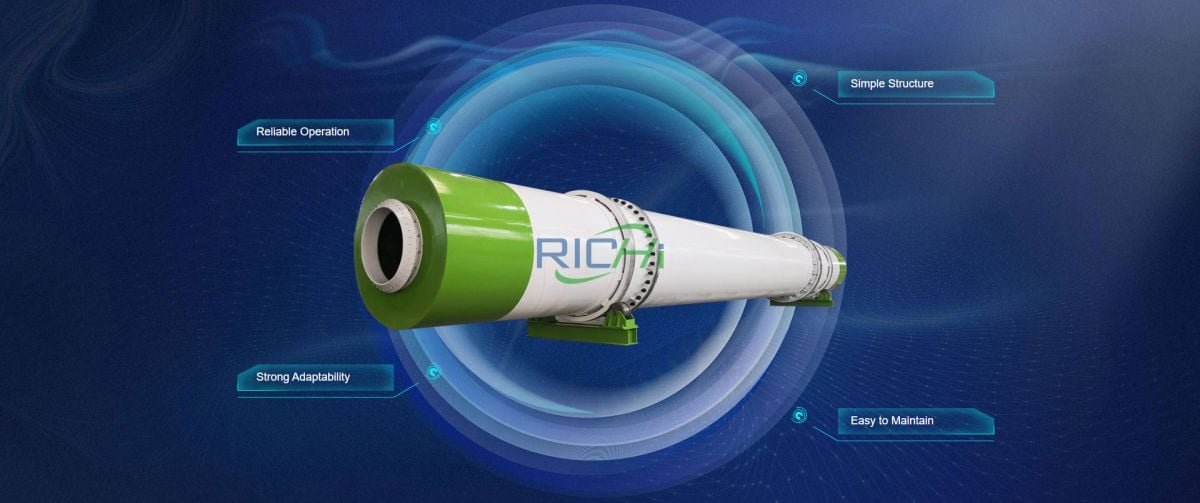

RICHI Machinery stands as a leader in the biomass pellet production industry, chiefly due to their remarkable technological innovations and profound expertise. One of the cornerstone aspects that differentiate RICHI Machinery from other manufacturers is their state-of-the-art equipment, specifically designed to enhance efficiency and product quality in the biomass pellet production line.

Their machinery solutions are built with advanced automation features, providing not only precision but also significant reductions in operational costs and downtime.

Another critical aspect is RICHI’s unrelenting dedication to research and development (R&D). Their R&D team is continually exploring new technologies and process improvements to advance biomass pellet production.

This forward-thinking approach ensures that their machines are equipped with the latest advancements that drive productivity and sustainability. By investing significantly in R&D, RICHI stays at the forefront of the industry, offering innovative solutions that cater to evolving customer needs and environmental standards.

Moreover, RICHI Machinery’s commitment to innovation extends beyond their equipment to incorporate smart manufacturing practices. This includes the integration of IoT (Internet of Things) capabilities, allowing for remote monitoring and control of the production process.

Such features add a layer of convenience and efficiency for operators, ensuring that any issues can be promptly identified and addressed, thereby minimizing the risk of production delays.

The expertise of RICHI Machinery is evidenced not only by their innovative technological solutions but also by their comprehensive service offerings. They provide extensive training, maintenance support, and consultancy services, ensuring that their clients can maximize the performance of their biomass pellet production lines. This holistic approach underscores their position as not just a manufacturer but a partner dedicated to the success of their clients.

In sum, RICHI Machinery’s blend of cutting-edge equipment, robust R&D initiatives, and commitment to innovation and client support solidifies their status as a premier choice in the biomass pellet industry. These technological advancements and expert services significantly contribute to the overall effectiveness and sustainability of biomass pellet production operations.

Market Position and Reputation of RICHI Machinery

RICHI Machinery stands out as a formidable player in the biomass pellet production line industry, leveraging its extensive experience and a robust market presence. With a history of delivering high-quality machinery, RICHI has cultivated a strong reputation for reliability and innovation. The company’s prominence can be evidenced by its consistent receipt of industry accolades and positive feedback from a broad customer base.

One of the defining aspects of RICHI Machinery’s market position is its impressive portfolio of customer testimonials. Businesses that have integrated RICHI’s biomass pellet production lines frequently cite improved operational efficiency and heightened product quality.

These testimonials highlight RICHI’s commitment to customer satisfaction and its ability to provide solutions tailored to specific business needs. The recurring theme of reliability and performance in customer reviews underscores the company’s strong market reputation.

Industry accolades further bolster RICHI Machinery’s standing. The company has been recognized for its excellence in engineering and innovation, receiving numerous awards that underscore its leadership in the biomass production sector.

These recognitions are a testament to RICHI’s continuous effort to adhere to the highest standards in quality and technological advancement. Such awards not only enhance the company’s credibility but also provide assurance to prospective customers regarding the robustness and effectiveness of their production lines.

RICHI Machinery’s successful projects and case studies offer compelling evidence of its capability in the biomass pellet production line domain. These projects, often highlighted in industry forums and trade shows, demonstrate the company’s versatility and expertise.

For businesses contemplating the establishment or upgrade of their biomass pellet production lines, RICHI represents a reliable partner with proven successful outcomes in varied operational contexts.

In essence, RICHI Machinery’s market position and stellar reputation make it a preferred choice among businesses. Its blend of customer-centric approach, commendable industry standing, and documented success in numerous projects emphasize why many enterprises choose RICHI to enhance their biomass pellet production capabilities.

Conclusion

Selecting the right manufacturer for a biomass pellet production line is a pivotal decision that can profoundly impact the efficiency, sustainability, and profitability of your operations. Throughout this guide, we have explored critical criteria to consider, such as experience, technological capabilities, customer support, and customization options.

It is essential to evaluate these factors meticulously to ensure that the manufacturer can meet your specific production needs and contribute to the success of your biomass processing endeavors.

The importance of making an informed choice cannot be overstated. A well-chosen manufacturer brings not only high-quality equipment but also ongoing support and innovative solutions that can adapt to changing market demands and environmental regulations. Therefore, assessing these attributes comprehensively is crucial to establish a long-term, reliable partnership that fosters growth and resilience in your business.

In light of the aforementioned considerations, RICHI Machinery stands out as a quintessential choice for those seeking a dependable biomass pellet production line manufacturer. With a robust portfolio of successful projects and a reputation for technological innovation, RICHI Machinery demonstrates an unwavering commitment to quality and customer satisfaction. Their professional team offers tailored solutions that cater to varied production requirements, ensuring optimal performance and efficiency.

RICHI Machinery’s prominent market position and positive client feedback further underscore their credibility and reliability. By choosing RICHI Machinery, you align your business with experienced professionals who leverage state-of-the-art technology to enhance your production capabilities. Thus, for a seamless and proficient biomass pellet production process, RICHI Machinery is an exemplary partner dedicated to fostering your operational success.