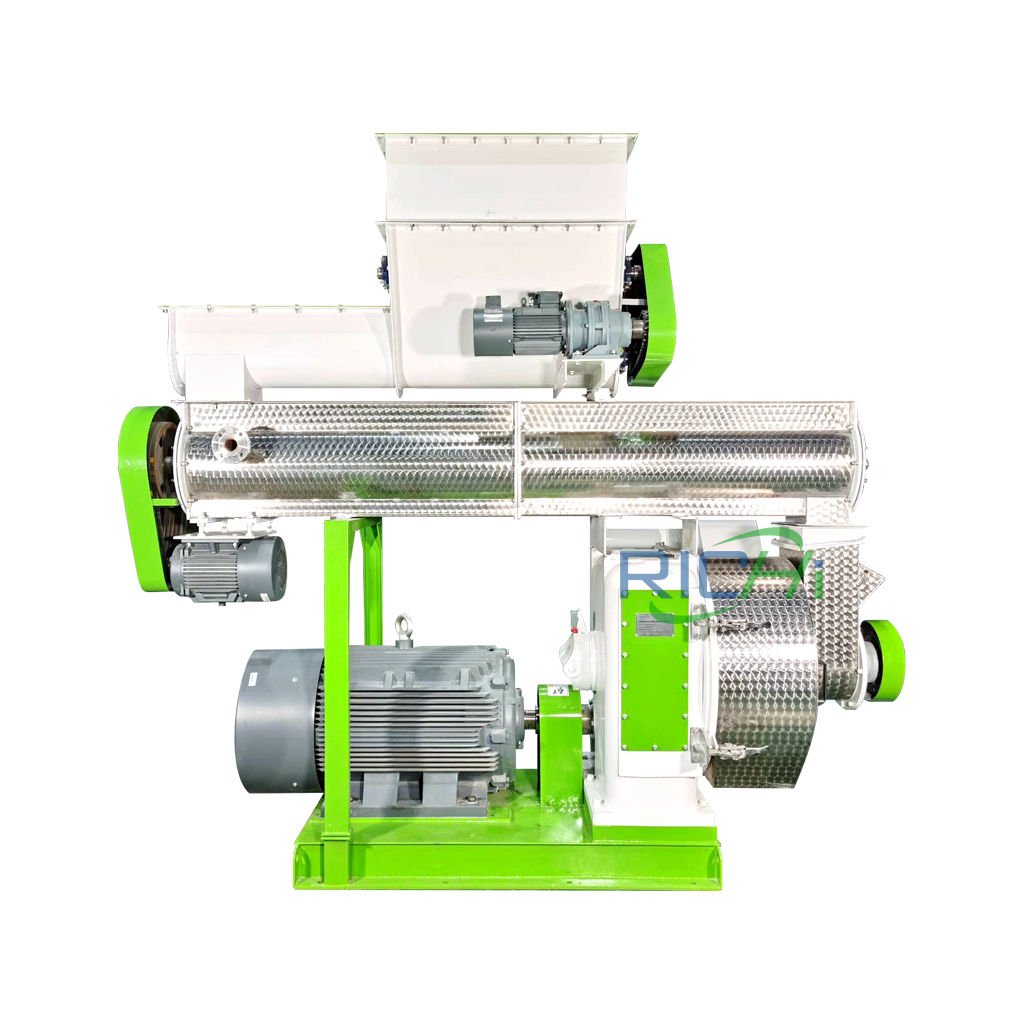

Maintaining a biomass pellet mill is crucial to ensuring it performs at optimal levels and delivers high-quality pellets consistently. If you want your biomass pellet mill to last for a long time, it’s essential to follow the recommended maintenance procedures. In this article, we will discuss the maintenance required for a biomass pellet mill.

Why is Maintenance Important for a Biomass Pellet Mill?

Maintenance is an essential aspect of ensuring the longevity and efficiency of your biomass pellet mill. Regular maintenance will keep the machine running smoothly, prevent costly breakdowns, and reduce the risk of accidents. A well-maintained biomass pellet mill will produce high-quality pellets that meet the required standards.

Related post: alfalfa pellet production line

Daily Maintenance

It’s essential to perform daily maintenance on your biomass pellet mill to ensure that it continues to function correctly. Daily maintenance includes inspecting the machine for any signs of damage, checking the oil level, and cleaning the machine. You should also check the temperature and vibration of the machine to ensure that it’s operating within the recommended range.

Weekly Maintenance

Weekly maintenance includes checking the blades, rollers, and bearings for any signs of wear and tear. You should also inspect the die and make sure that it’s not clogged. Cleaning the machine thoroughly is also crucial at this stage. You can use compressed air to blow out any debris or dust that may have accumulated inside the machine.

Monthly Maintenance

Monthly maintenance involves checking the electrical components of the biomass pellet mill. You should inspect the wiring and connections for any signs of damage or wear and tear. It’s also crucial to check the gearboxes, chains, and belts and lubricate them if necessary.

Related post: https://www.richipelletmachine.com/alfalfa-pellet-production-line/

Yearly Maintenance

Yearly maintenance includes a complete overhaul of the biomass pellet mill. You should disassemble the machine, inspect each component thoroughly, and replace any worn-out parts. It’s also essential to clean the machine thoroughly during this maintenance period.

Conclusion

In conclusion, maintaining a biomass pellet mill is essential to ensuring it continues to perform at optimal levels. Regular maintenance will keep the machine running smoothly, prevent costly breakdowns, and reduce the risk of accidents. Daily, weekly, monthly, and yearly maintenance are all critical aspects of keeping your biomass pellet mill in top condition. By following the recommended maintenance procedures, you can ensure that your biomass pellet mill lasts for a long time and delivers high-quality pellets consistently.

For details please contact: pellet maker

WhatsApp:86 138 3838 9622

Email:enquiry@richipelletmachine.com