1. About floating fish pellet machine

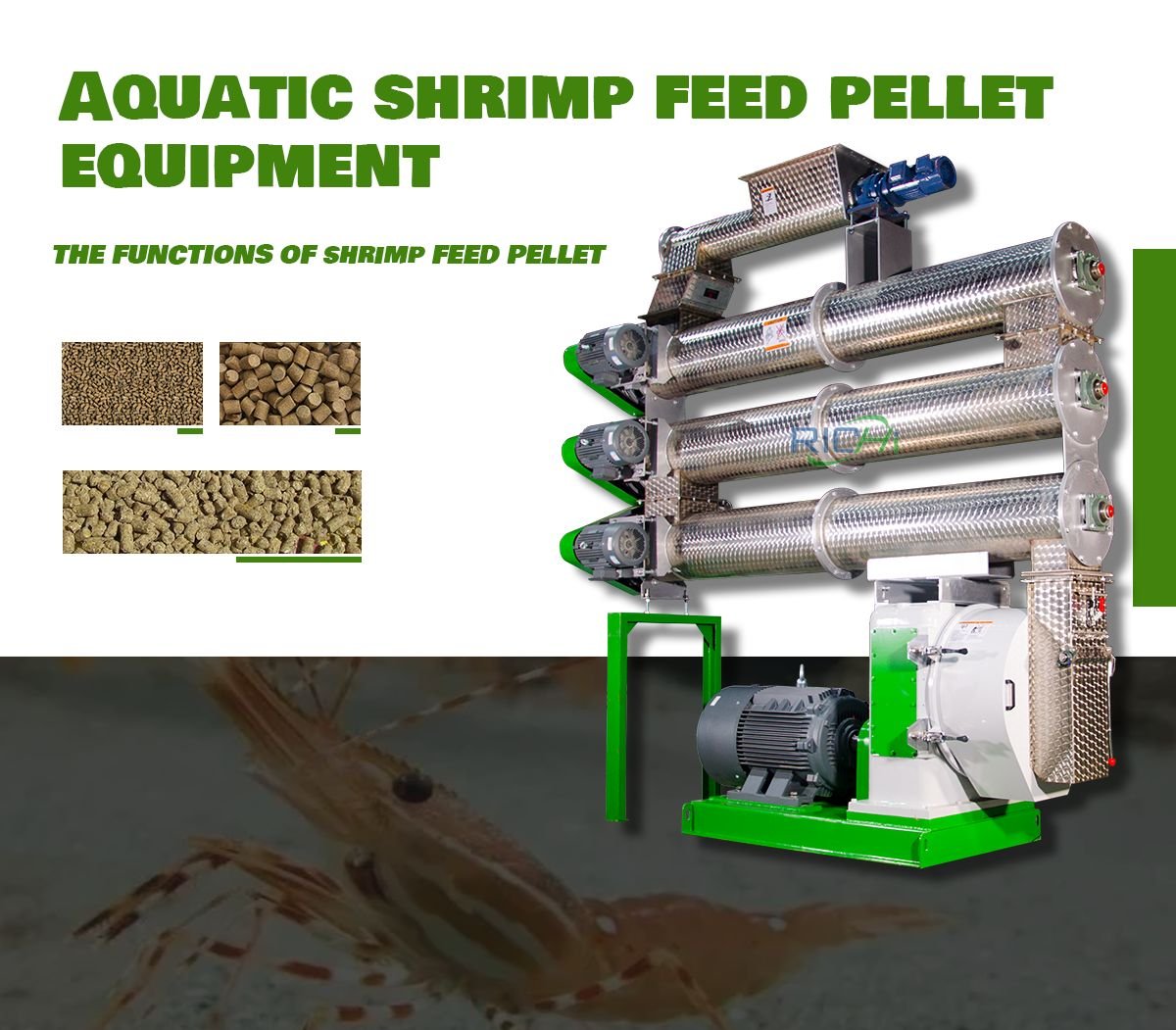

- Products: fish feed, shrimp and crab feed, sinking and floating feed products

- Shape: Process and customize various specifications of rice grains according to market requirements

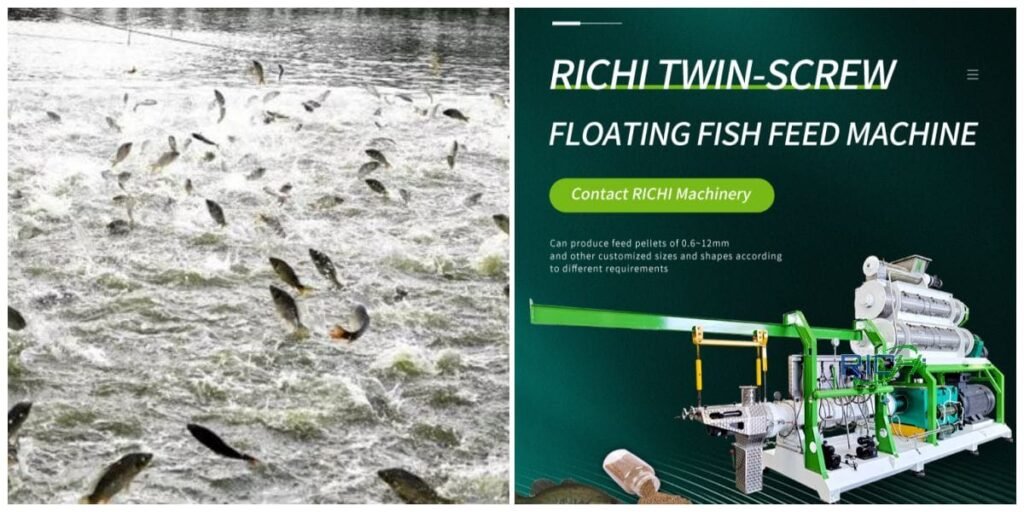

- Production process: The puffed fish feed is produced by twin-screw floating fish pellet machine extrusion technology. After mixing various raw materials, they are fused with high temperature and high pressure to form feed pellets.

After passing through a feed dryer, they are slowly dried at low temperature for 30-40 minutes, and dried with moisture. To meet the quality requirements, the appearance of the product will not shrink, not break, no pores, and the nutritional value will not be destroyed.

Finished feed with no burr edges and corners on the surface of the product after the fine drum is sprayed and seasoned. The raw materials are fully kneaded and mixed in the floating fish pellet machine extruder, the starch is denatured, and the protein is matured; various nutritional functions are added.

It can improve the nutritional performance of the product and is suitable for all kinds of cultured species that need supplementary nutrition.

- Technical process: raw material crushing-raw material mixing-floating fish pellet machine-drying-oil spraying and vitamin-spraying-cooling-storage.

- Equipment configuration:

Pulverizer, Powder Mixer, Screw Conveyor, Twin-screw extrusion floating fish pellet machine (Single and Double Rod Modulators, Small Steam Generator), Vibrating screen, Air conveyor, Multi-layer circulating belt type drying box, Air conveyor, Oil spray and vitamin seasoning line, Conveyor, Material storage warehouse.

(This configuration is for reference only for small equipment, and large floating fish pellet machine is configured separately according to actual production needs)

2. Floating fish pellet machine features:

- The whole floating fish pellet machine is made of stainless steel.

- With twin-screw extrusion technology, the screw of floating fish feed making machine adopts a special arrangement to increase the flexibility of the product. The extrusion bin is specially equipped to ensure product consistency and nutritional balance.

- The drying box adopts the circulating drying technology, the circulating hot air circulation system, the thermal efficiency utilization rate is high, the drying is uniform, and the airtightness is good.

- The feed needs 30-40 minutes to be dried in the drying box, and the feed is about 10kg per square meter. The drying area is 10 m2 for every 100 kilograms of raw materials. Every 100kg of raw material needs to be dehydrated 12-15kg. Drying oven drying temperature: 85-90℃.

- By changing the production formula, it is possible to produce floating fish feed, shrimp and crab feed that are popular in the market.

- Add related floating fish pellet machine to produce high-end fish feed.

3.Types of fish feed machinery production line

(1) xl65-P series floating fish pellet machine production line

- Output: 100-150 kg per hour

- Actual power consumption: 70-90 degrees per hour

- Equipment placement Production and use of plant area: 40-50 square meters

- Labor: 2-3 people operate

- Equipment configuration: mixer-automatic feeder-floating fish feed extruder-conveyor-dryer-automatic conveyor-seasoning machine-fuel injection machine-cooling conveyor.

(2) xl70-P series floating fish pellet machine production line

- Output: 200-250 kg per hour

- Actual power consumption: 90-110 degrees per hour

- Equipment placement Production and use of plant area: 50-60 square meters

- Labor: 2-3 people operate

- Equipment configuration: mixer-automatic feeder-floating fish feed extruder machine-conveyor-dryer-automatic conveyor-seasoning machine-fuel injection machine-cooling conveyor.

(3) xl85-P series floating fish pellet machine line

- Output: 400-550 kg per hour

- Actual power consumption: 190-210 degrees per hour

- Equipment Placement Production Plant Area: 90-120 square meters

- Labor: 2-3 people operate

- Equipment configuration: mixer-automatic feeder-floating fish pellet machine-conveyor-dryer-automatic conveyor-seasoning machine-fuel injection machine-cooling conveyor.

(4) xl95-P series floating fish pellet machine line

- Output: 800-1200 kg per hour

- Actual power consumption: 110-130 degrees per hour

- Steam usage: 1.5-2 tons of steam boilers, provided by customers

- Equipment Placement Production Plant Area: 150-200 square meters

- Labor: 2-3 people operate

- Equipment configuration: large horizontal mixer-bucket automatic feeder-raw material storage bin-double shaft conditioner-floating fish pellet machine-conveyor-steam heating large-scale dryer-automatic conveyor-seasoning machine-fuel injection machine -Box cooler.

3.Floating fish pellet machine manufacturer

Richi Machinery is a professional team composed of experts who have been engaged in floating fish pellet machine engineering technology research for a long time. Since 1995, we have carried out systematic research on the application of twin-screw floating fish pellet machine and extrusion technology in food, feed and other industries.

We have accumulated a lot of experience in the production technology and production process of breakfast cereal, extruded snack food, textured soybean protein, regenerative nutritional rice and extruded puffed infant nutritional rice flour, pet feed, aquatic feed, industrial intermediates, etc.

Looking back on the past, after more than 20 years of trials and hardships, along with the development of the floating fish pellet machine industry, with the support and help of thousands of end users, it has gone through a development process from small to large, from weak to strong.

In the rapidly developing field of puffing machinery industry, Richi Machinery focuses on the research and development, manufacturing and service of floating fish pellet machine products, with the core values of innovation, precision, passion, fairness and service as the driving force, in order to continuously improve product quality and service, better give back to customers.