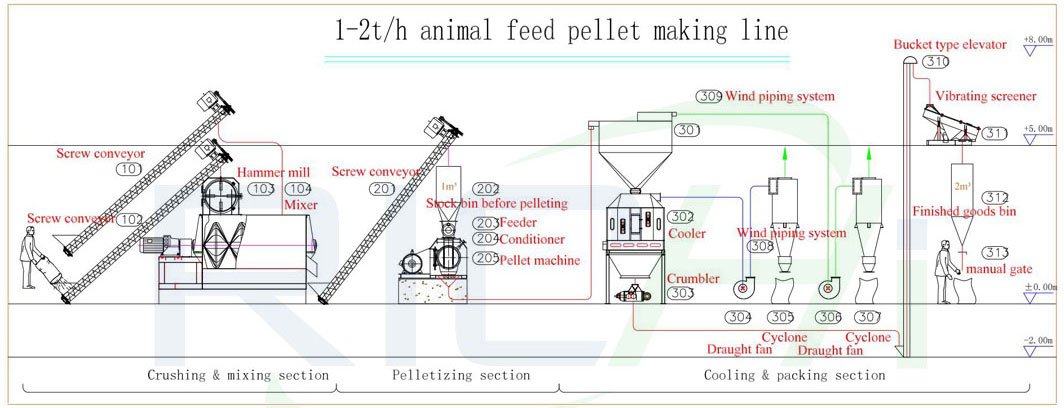

1-2 TPH Feed Pellet Production Line

Name: 1-2 tph feed pellet production line

Capacity: 1-2 tph

Certification: CE & SGS & ISO

Application: Can be used in pig, chicken, rabbit, cattle, cow, sheep, fish, shrimp feed pellet production line

Name: 1-2 tph feed pellet production line

Capacity: 1-2 tph

Certification: CE & SGS & ISO

Application: Can be used in pig, chicken, rabbit, cattle, cow, sheep, fish, shrimp feed pellet production line

Step 1. Determine the processing scale of the feed production line

Step 2. Determine feed processing technology and select related equipment

1. Variety, quality and output requirements of the finished product

2. Feed processing formula;

3. Production process and equipment;

4. Performance and quality of equipment;

5. Equipment cleaning and maintenance;

6. Production cost and use cost;

7. Standardization, serialization and generalization of parts;

8. Construction space of the project;

9. Environmental protection fire and other national requirements

Step 3. Selecting the control mode

1. Capacity size

2. Complicated process

3. How many product varieties

Step 4. Selection of plant structure form

1. All-concrete structure

2. Semi-steel structure

3. All-steel structure

4. 4Sliding mode structure

Step 5. Plan the general plan of the plant area

1. Considerations:

2. Logistics distance

3. Safety regulations

4. Avoid mutual interference

5. Factory center of gravity

Step 6. Visual effect

The overall layout of a feed mill varies depending on the production nature, scale, and process of the feed mill. usually:

1. The building should account for 30-35% of the total area of the plant

2. Factory roads account for 13% of the total area

3. The green area is not less than 10-15% of the entire plant area

Grain hammer mill: 15-200 (11 kw)

Pellet mill : SZLH-250 (22 kw)

Conditioner: stainless steel conditioner (2 kw)

Single-axial spiral belt mixing machine HJJ50B (7.5 kw)

Cooler: Counterflow cooling machine SKLN1.0*1.0 (1 kw)

Pellet crumbler: SSLG15*100 (5.5 kw)

Bucket elevator, screw conveyor, cyclone, vibrating screen, draft blower, etc.

Total power: 65 kw.

Production line Floor space: 6m * 4m * 5m (L * W * H)