poultry feed pellet machine

livestock feed pellet machine

Aqua feed pellet machine

fish feed pellet extruder

pet food pellet extruder

Poultry Feed Pellet Making Machine Solution

Poultry Feed Pellet Machine

- Suitable for all poultry animals (layers, broilers, turkeys, ducks, geese, etc.).

- Produces 2–6 mm feed pellets for different growth stages.

- Ring die pelleting technology, capacity from 1–40 tons/hour.

- Stainless steel feeder and conditioner for long service life.

Poultry Feed Production Line

We provide complete poultry feed production lines ranging from 1- 100 tons/hour. We can customize pellet lines, create dedicated powder lines, and “pellet + powder” composite lines to flexibly adapt to the different needs of laying hens, broilers, ducks, etc.

Livestock Feed Pellet Making Machine Solution

livestock feed production line

The entire livestock feed production line is highly automated. It adopts a Siemens PLC remote monitoring system and is equipped with a high-efficiency crusher, precision batching scale, twin-shaft mixer, ring die livestock feed pellet machine, and automatic feed equipment to ensure high output and stable operation.

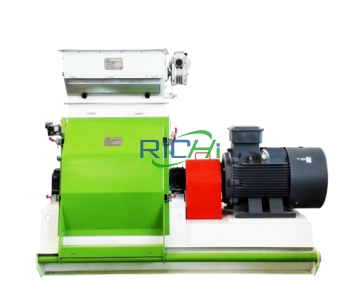

livestock feed pellet machine

- Designed for cattle, pigs, sheep, camels, rabbits, horses, and other livestock and ruminants.

- Adjustable pellet size: 4–10 mm; capacity 1–100 tons/hour.

- Main motor power 37–315 kW; gear drive is more efficient than belt drive.

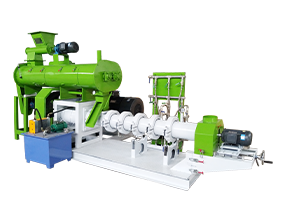

Aqua Feed Pellet Making Machine Solution

Aquatic Feed Pellet Extruder

- Utilizing screw extrusion technology, this extruder is suitable for producing high-quality feed for a wide range of aquatic animals.

- Suitable for high-protein formulations, ensuring thorough cooking of fishmeal and soybean meal, thus improving digestibility.

- Output range: 0.3–10 tons/hour; pellet diameter: 1–12 mm, covering all stages from fry to adult fish.

Aquatic Feed Production Line

We offer aquatic feed production lines ranging from 0.3 to 30 tons/hour, covering the entire process from ultra-fine grinding and mixing to twin-screw extrusion, multi-layer drying, oil spraying system, cooling and screening, and automated packaging.

We can produce various aquatic feeds, including tilapia feed, sea bass feed, shrimp feed, and crab feed. The entire line is equipped with a precision oil spraying system.

Complete equipment solutions for all types of animals

RICHI Machinery provides feed production line solutions covering all animal breeds. From poultry to livestock and aquaculture, we have specialized equipment configurations tailored to the physiological characteristics and nutritional needs of each animal. No matter what animals you raise or what production capacity you require, RICHI has mature technical solutions and extensive project experience to serve you.

Duck feed production line

Goose feed production line

Pigeon feed production line

Cow feed production line

Goat feed production line

Horse feed production line

Camel feed production line

Rabbit feed production line

Crab Feed production line

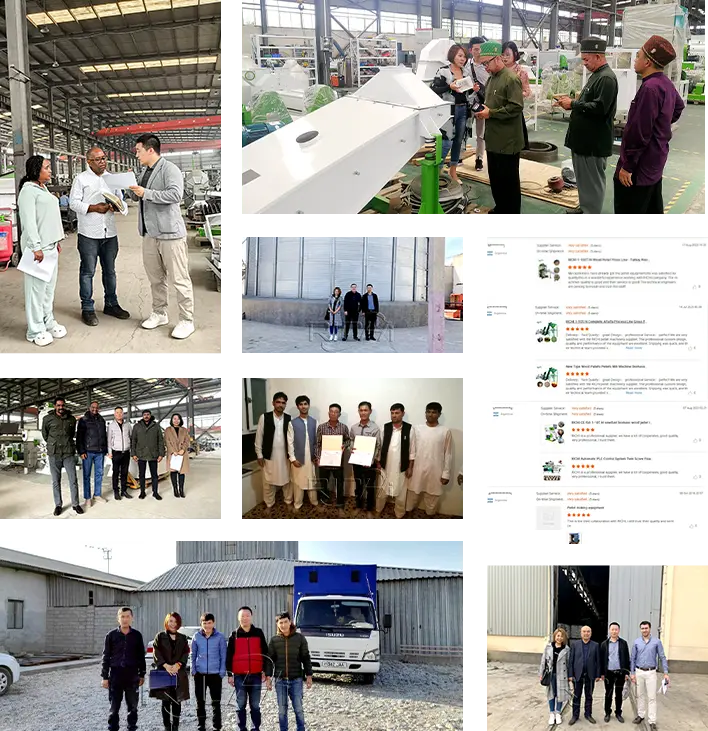

Feed Pellet Making Equipment Projects

Here, we showcase RICHI Machinery’s real-world projects across six continents. With over 30 years of experience, our feed pelleting equipment has been exported to more than 140 countries, consistently earning high praise and repeat orders. Whether for large-scale ranches, integrated feed mills, or production line optimization, RICHI’s engineering team helps customers worldwide build efficient and sustainable feed production systems.

Asia

North America

Europe

Africa

South America

Oceania

Asia | Japan | Hiroshi Tanaka

★★★★★

Our salmon feed production line in Hokkaido has been operating stably for over a year. RICHI’s complete system precisely controls the fineness of the powder and the extrusion and maturation effect, resulting in excellent water stability of the pellets. We are extremely satisfied with RICHI’s equipment.

North America | USA | Marisabel Hart

★★★★★

We operate a chicken and cattle compound feed mill. RICHI’s equipment is highly automated, requiring almost no manual labor, and the pellet quality meets North American market standards. We consider it a very successful investment.

Africa | South Africa | Peter Ndlovu

★★★★★

Our poultry and beef cattle feed lines operate up to 16 hours a day, producing uniform and well-formed pellets. RICHI engineers provided on-site commissioning and training; the team was very professional, improving our overall capacity.

Feed Processing Line Project Videos

Below is a video showcasing a large-scale production line case study we have completed. As a manufacturer specializing in feed equipment, RICHI has provided complete feed equipment solutions to over 140 countries worldwide.

Every year, we receive numerous additional and repeat orders from our clients, which fully demonstrates the reliability of RICHI equipment and our technological strength. Whether you need a complete feed pellet production line solution for poultry, livestock, or aquaculture, or wish to customize a production system for a specific animal feed, or optimize and upgrade existing equipment, our professional technical engineers can provide you with feed production solutions tailored to your needs.

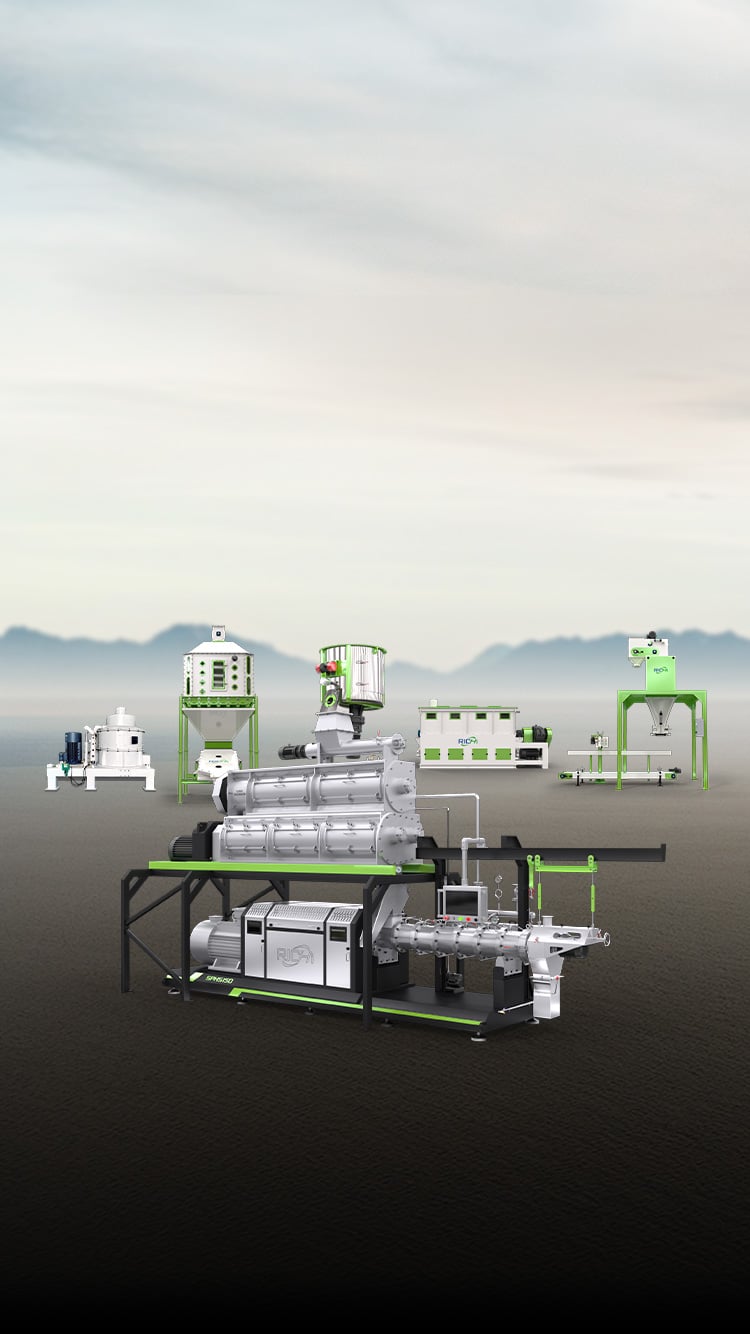

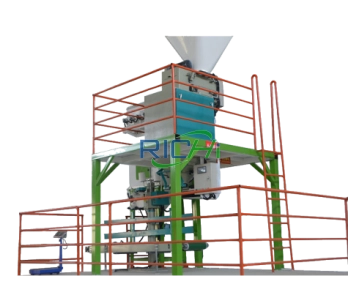

Auxiliary Equipment Display for a Complete Feed Mill

Here you will see auxiliary equipment commonly used in feed mills for material conveying, dust removal, metering, and packaging. Developed from RICHI’s years of industry experience and applied in over 1000 projects worldwide, this equipment helps your feed mill operate more stably and efficiently. Whether building a new production line or optimizing an existing plant, the equipment here provides valuable solutions.

RICHI Machinery

Founded in 1995, RICHI Machinery is a professional manufacturer specializing in complete feed machinery engineering projects. It provides comprehensive services to global clients, including project consulting, process design, equipment manufacturing, installation, commissioning, and technical support.

Over the years, RICHI’s feed equipment has been exported to more than 140 countries worldwide, with over 1,000 completed feed projects for poultry, livestock, and aquaculture, widely used in feed mills of all sizes. With its stable and reliable equipment quality, comprehensive service system, and rich engineering experience, RICHI has become a leading supplier of overall solutions for feed mills globally, and a trusted brand with numerous long-term clients and repeat purchases.

ABOUT US

Founded in 1995, RICHI Machinery specializes in feed processing equipment and complete feed mill engineering. We have developed mature expertise in poultry, livestock, ruminant, and aquaculture sectors, covering everything from needs analysis and engineering design to equipment delivery, installation, and long-term service. With reliable performance and solid engineering capabilities, RICHI’s equipment operates in over 140 countries with more than 1,000 feed production lines installed, making us a trusted partner for feed companies worldwide.

RICHI has two large production bases in Kaifeng and Jiaozuo, Henan Province, covering 80,000 square meters with over 500 workers. Our factories feature advanced equipment including CNC cutting, CNC drilling, automatic welding, dynamic balancing testing, and painting lines. Strict quality control ensures each piece of equipment undergoes thorough testing. These manufacturing capabilities enable RICHI to provide structurally reliable, energy-efficient feed equipment with extended lifespan, delivering solid engineering support for various feed mill projects.

Feed Production Solutions

We provide complete feed processing solutions tailored to different animal categories. Whether for poultry, livestock, or aquaculture, our feed production lines and machines are designed to deliver stable output, consistent feed quality, and flexible configurations for farms and feed mills of all sizes.

Poultry feed machine

aqua feed machine

livestock feed machine

Project Service System

From preliminary research to solution design, from equipment manufacturing to installation and commissioning, and then to long-term maintenance support, we provide stable and reliable one-stop service guarantees to global clients through rigorous, standardized, and traceable engineering processes.

Project Requirements Analysis

We provide preliminary consulting from scratch, including process requirements, raw material analysis, capacity planning, and budget assessment. Our engineering team offers professional advice and feasible solutions based on each project’s specific circumstances, helping clients clarify their direction.

production process design

After understanding client needs, our technical team conducts detailed process design covering plant layout, equipment configuration, logistics flow, and energy consumption. All designs draw from years of engineering experience and field cases to ensure efficiency and stability.

Equipment Manufacturing

We manufacture all equipment in our modern Kaifeng and Jiaozuo factories. Production lines use CNC cutting, automatic welding, dynamic balancing testing, sandblasting, and baking paint processes, strictly controlling quality to meet global usage standards.

Installation and Commissioning

During implementation, we provide on-site installation, process commissioning, and operator training to get production lines running quickly. After completion, we offer remote technical support, spare parts service, regular follow-ups, and lifetime after-sales to help resolve any operational issues.